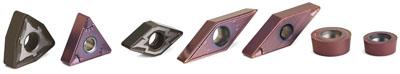

Seco has increased the application range of its wear-resistant TH1000 and TH1500 turning insert grades by adding new positive and negative geometries, chip breakers and nose radius sizes to the line. The additions allow manufacturers that process hardened steels, superalloys and cast irons to further increase their machining capabilities.

With its reliable edge toughness and high chip resistance qualities available across a broader product range, the TH1000 TiSiN-TiAlN nanolaminate PVD-coated grade enables manufacturers to productively tackle a wider variety of ISO H5-H10 applications as well as maintain long tool life when machining hardened steels, from 50 to 62 HRC, hard surfaced components and superalloy materials.

TH1000 excels in finishing operations and performing interrupted cuts in harden steels. With respect to machining superalloys, such as Inconel 718, Waspaloy and Nimonic C263, the grade brings fast cutting speeds to continuous finishing and semi-finishing operations. Furthermore, the latest TH1000 chipbreaker inserts bring optimum chip control and high process security to a broader working range.

For processing hardened steels from 40 to 55 HRC, the Duratomic TH1500 grade, through its product expansion, allows manufacturers to excel in an increased number of ISO H10-H15 applications that require high cutting data and continuous-cut operations. TH1500 also provides superior finish turning of grey and ductile cast irons in applications with low-to-moderate cutting speeds.

Furthermore, because of its advanced grade profile, which includes an α-based Al2O3 CVD coating, Ti (C,N) middle layer and a super fine grain substrate, TH1500 makes a great alternative to CBN and ceramic cutting tools in situations that involve machining hardened steel workpieces in unstable conditions.

Overall, the new additions to the TH1000 and TH1500 product lines significantly increase the number of optimal turning solutions available to parts manufacturers serving the aerospace, automotive and energy industry segments. The additions also allow the company to provide total solutions for machining challenging materials. TH1000, for example, complements the TS2000 and CP200 carbide grades and CBN170 grade to form a complete finish machining package for superalloy materials. TH1500, because of its superior finishing turning capabilities in grey and ductile cast iron, nicely complements the company’s TK1001 and TK2001 grades.

Contact Details

Related Glossary Terms

- cast irons

cast irons

Cast ferrous alloys containing carbon in excess of solubility in austenite that exists in the alloy at the eutectic temperature. Cast irons include gray cast iron, white cast iron, malleable cast iron and ductile, or nodular, cast iron. The word “cast” is often left out.

- chemical vapor deposition ( CVD)

chemical vapor deposition ( CVD)

High-temperature (1,000° C or higher), atmosphere-controlled process in which a chemical reaction is induced for the purpose of depositing a coating 2µm to 12µm thick on a tool’s surface. See coated tools; PVD, physical vapor deposition.

- chipbreaker

chipbreaker

Groove or other tool geometry that breaks chips into small fragments as they come off the workpiece. Designed to prevent chips from becoming so long that they are difficult to control, catch in turning parts and cause safety problems.

- cubic boron nitride ( CBN)

cubic boron nitride ( CBN)

Crystal manufactured from boron nitride under high pressure and temperature. Used to cut hard-to-machine ferrous and nickel-base materials up to 70 HRC. Second hardest material after diamond. See superabrasive tools.

- ductile cast irons

ductile cast irons

Ferrous alloys in which graphite is present as tiny balls or spherulites. The spheroidal graphite structure is produced by adding one or more elements to the molten metal, among which magnesium and cerium are commercially important. Approximate composition of ductile cast irons is: 3.0 to 4.0 percent carbon, 0.1 to 1.0 percent manganese, 1.8 to 2.8 percent silicon, 0.1 percent (maximum) phosphorus and 0.03 percent (maximum) sulfur. Typical ductile cast iron grades are D-4018, D-4512, D-5506 and D-7003 by definition of the Society of Automotive Engineers; 60-40-18, 65-45-12, 80-55-06, 100-70-03 and 120-90-02 by definition of the American Society for Testing and Materials. Also known as nodular cast irons.

- superalloys

superalloys

Tough, difficult-to-machine alloys; includes Hastelloy, Inconel and Monel. Many are nickel-base metals.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.