CNC turning center for high-volume production of small, intricate parts

CNC turning center for high-volume production of small, intricate parts

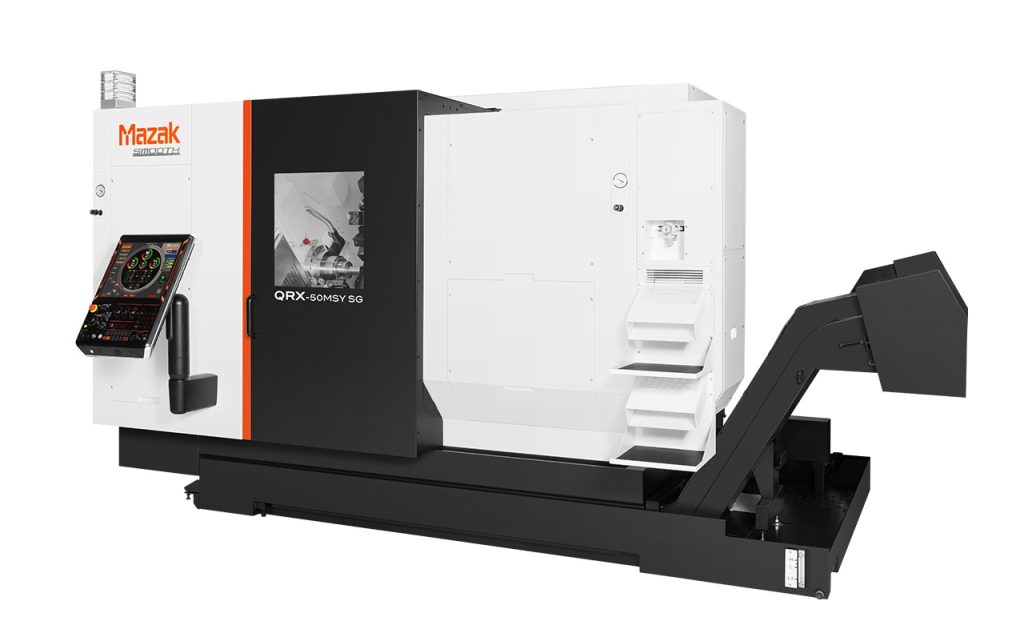

Mazak is unveiling its QRX-50MSY CNC turning center at the company's Discover 2025 event, Oct. 6-10, that provides manufacturers the speed and versatility for high-volume production of small, intricate parts in a compact, affordable machine.

Mazak is unveiling its QRX-50MSY CNC turning center that provides manufacturers the speed and versatility for high-volume production of small, intricate parts in a compact, affordable machine.

Debuting at the company's Discover 2025 event at its Florence, Kentucky, facility, the QRX-50MSY's combination of milling capability, second turning spindle and Y-axis functionality with advanced technology, productivity and value delivers exceptional performance for shops machining small parts such as EV input shafts, mid-shafts, valve fittings, and other components exceeding 2" in diameter.

The QRX-50MSY is the latest adaptation of Mazak's versatile and efficient HQR Series 2-turret/2-spindle CNC turning center, which features similar milling and Y-axis functions. The QRX-50MSY boasts a 15% smaller footprint with floor dimensions of 119.3" (3,030 mm) by 86.6" (2,200 mm) while maintaining throughput and reduced cycle times.

Additionally, the QRX-50MSY's modular design uses common machine components such as identical left and right spindles, upper and lower turrets and upper and lower carrier drives. The modular nature of the QRX-50MSY keeps machine cost down to maximize a manufacturer's return on investment when producing small parts.

The QRX-50MSY sports a maximum bar diameter capacity of 2.0" (50 mm) with a 6" (152 mm) diameter chuck and features a slant bed design. The main and second spindles use 20 hp (15 kW) motors that provide maximum speeds of 6,000 rpm. The 12-station/24-tool position upper and lower turrets feature 7.0 hp (5.3 kW) rotary tool spindles that offer maximum speeds of 6,000 rpm.

The machine's toolholding utilizes a BMT (Basic Metric Tooling) 45 interface for fast, precise tool changes and optimized performance. The interface uses static and driven tools and supports a wide range of tool holder types, including radial, axial and angular holders. The BMT 45 interface allows tools to be rotated 180 degrees for use on second operations, eliminating the need for tool changes between the operations.

The QRX-50MSY is equipped with a work unloader over the top of the second spindle that shops can equip with a gripper or parts bucket to remove parts from the machine. An auto parts catcher mounted on the lower turret catches parts at the second spindle head, or positioned beneath the main spindle, it can also accommodate end-of-bar remnants.

The machine comes standard with the Mazatrol SmoothG CNC that includes Mazatrol conversational programming as well as EIA-ISO G-code programming capabilities. The control provides unsurpassed ease of operation with its 19-inch touch screen and 3D model-based graphical user interface for intuitive operation like that of smartphones and tablets. The control also incorporates a wide variety of advanced programming functions for complete ease of use and high-speed, high-accuracy machining performance.

Every Mazak machine is backed by Mazak MPower Complete Customer Care, the industry's most comprehensive machine support program. Plus, Mazak Capital Equipment Financing (MCEF) allows shops to easily move their manufacturing forward with one-stop, factory-direct financing on Mazak equipment.