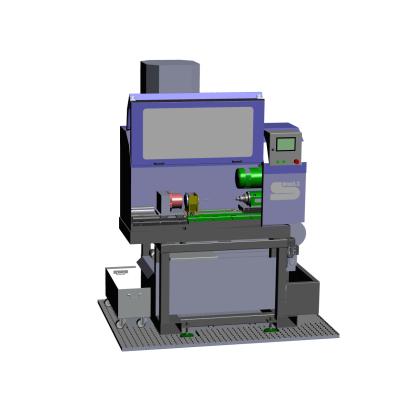

The Suhner Industrial Products Corp., Rome, Ga., recently announced that its SOMEX division offers custom-made deep-hole drilling solutions capable of drilling up to 12mm diameters and as deep as 100x diameter. Utilizing a modular component concept, the SOMEX deep-hole drilling solutions can be integrated directly into transfer machines, special purpose machines or conventional machines, according to a Feb. 2 company news release.

SOMEX routinely conducts tests with tools and material to prove out design and performance of each customized deep-hole drilling machine, the company said. Tests, conducted at the factory, use specific production tools under real production conditions. SOMEX uses single cutting edge and carbide spiral drills up to 70x the diameter. Using this approach, Suhner said that SOMEX is able to deliver practical and realistic results to its customers.

The deep-hole drilling process typically requires either a pilot-drill 1.5x the diameter or a drill guide bushing, which is then followed by the deep-hole drilling process. The unique SOMEX design concept combines the guide bushing with a chip basket, allowing both items to travel in unison. The movement of the guide bushing is air-driven, which is said to help provide a much closer contact to the part while preventing the escape of the coolant medium.

For longer deep-hole drilling applications, it may be necessary to integrate a support bushing to stabilize the deep-hole drilling tool, Suhner added.

For deep hole drilling applications above 18mm diameters, SOMEX has the option to equip its MAX machining units with drilling systems from its BTA- or EJEKTOR lines. In these applications, the coolant and chip management is accomplished through the spindle center. The emulsion is collected at the backend of the spindle, filtered and pressurized to re-enter the coolant system. This solution is often used in high-volume precision parts manufacturing such as in automotive and other industries.

Contact Details

Related Glossary Terms

- bushing

bushing

Cylindrical sleeve, typically made from high-grade tool steel, inserted into a jig fixture to guide cutting tools. There are three main types: renewable, used in liners that in turn are installed in the jig; press-fit, installed directly in the jig for short production runs; and liner (or master), installed permanently in a jig to receive renewable bushing.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- drilling machine ( drill press)

drilling machine ( drill press)

Machine designed to rotate end-cutting tools. Can also be used for reaming, tapping, countersinking, counterboring, spotfacing and boring.

- drilling tool ( drill or drill bit)

drilling tool ( drill or drill bit)

End-cutting tool for drilling. Tool has shank, body and angled face with cutting edges that drill the hole. Drills range in size from “microdrills” a few thousandths of an inch in diameter up to spade drills, which may cut holes several inches in diameter. Drills may have tapered shanks with a driving tang and fit directly into a spindle or adapter, or they may have straight shanks and be chuck-mounted. The rake angle varies with the material drilled. Styles include twist drills, straight-flute drills, half-round and flat drills, oil-hole drills, indexable drills and specials.

- emulsion

emulsion

Suspension of one liquid in another, such as oil in water.