Scytec Consulting Incorporated celebrates its tenth year of transforming shop floors worldwide with DataXchange making significant strides in terms of value added to their machine monitoring platform including additional data collection protocols, Microsoft Teams integration for instantaneous alerts on machine performance and more. Scytec DataXchange is a machine monitoring communication system that offers a cloud subscription with a no-commitment month-to-month pricing option, or as an on-premise deployment.

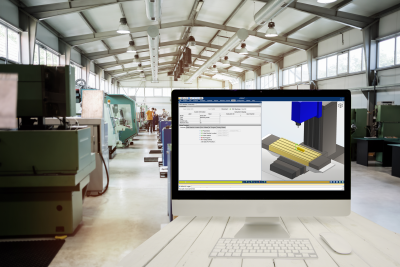

Scytec Consulting Incorporated is proud to announce a partnership with CGTech and the integration of DataXchange into the Digital Twin standard VERICUT. This is an incredible offering for the manufacturing industry at large by making CGTech VERICUT infinitely more valuable by adding a robust machine monitoring solution via CGTech’s new module called CNC Machine Connect in the launch of VERICUT 9.3 to enhance the quality of the simulation. Through CNC Machine Connect, end users have the Pre-Check option which verifies key aspects of machine setups, such as main NC programs, subprograms, work offsets, cutting tools, and their length offsets matching the simulations produced in VERICUT. Located mismatches can be corrected to ensure the program will continue to run with no unwanted effects. CNC Machine Connect currently supports modern Fanuc 0i and 30i series controls.

Future releases will see expanded CNC control types and the ability to live stream the machining process and review data post machining to see how the data compares to the VERICUT project with insight into axis position, overrides, tooling, and more. End users will have the ability to investigate potential issues that may have caused parts to be out of specification, review any modifications to the NC program subroutines, or feed rates and spindle speeds.

Contact Details

Contact Details

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- numerical control ( NC)

numerical control ( NC)

Any controlled equipment that allows an operator to program its movement by entering a series of coded numbers and symbols. See CNC, computer numerical control; DNC, direct numerical control.