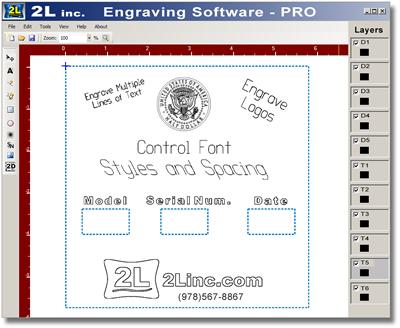

The PRO 1 and PRO 2 engraving software programs from 2L inc. are full featured, simple-to-use drawing programs that produce standard G code NC files that are compatible with virtually any CNC. Both programs allow creating precise engraving layouts using multiple fonts, drawn shapes, lines and incremental serial numbers. The engraving layouts can be precisely located using reference geometry or guidelines, control the text orientation, alignment, spacing and size of multiple instances of text. The new cycle time monitor feature can assist in evaluating and improving engraving cycle times by changing engraving parameters such as font selection and feed rates. One of 2L's single-line engraving fonts is included with each software program to help reduce cycle time. The PRO 2 program adds an additional element to the PRO 1 features, providing 4th axis engraving capability, which easily wraps the engraving around a cylinder for 4-axis rotary CNC milling machines or multiaxis lathes.

Contact Details

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- numerical control ( NC)

numerical control ( NC)

Any controlled equipment that allows an operator to program its movement by entering a series of coded numbers and symbols. See CNC, computer numerical control; DNC, direct numerical control.