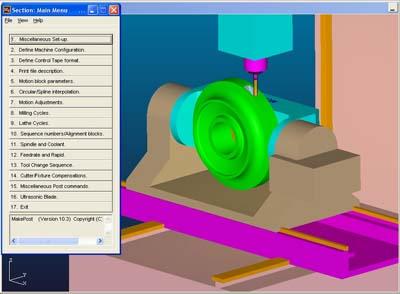

Numerical Control Computer Sciences has announced that the latest version of their universal postprocessor, PostWorks, can be integrated to run within CATIA V5. PostWorks has long had the ability to read and process both CATIA V4 and V5 output files, however the user would have to launch PostWorks outside of CATIA. The latest version of PostWorks allows the user to launch PostWorks without leaving the CATIA environment. PostWorks is a high-end universal postprocessor, which generates precise NC code for a wide variety of machines, including mills, lathes, and multi-tasking machines. In addition, PostWorks is compatible with all popular CNC controls including Heidenhain, Siemens, and Fanuc. CATIA users can benefit from PostWorks ability to convert complex 5-axis tool paths to NC code that efficiently controls the movement and speed of sophisticated multi-axis machines. For example, PostWorks' unique look-ahead function automatically reduces excessive rotary axis movement and prevents potential machine over travel which are both common problems with certain rotary axis configurations. Many companies use a variety of CAM systems. PostWorks provides a single postprocessor solution thereby eliminating the need to develop duplicate postprocessors for each CAM system. PostWorks is compatible with all major CAM systems including CATIA, NCL, UG, and Mastercam. Add-ons to PostWorks include sophisticated simulation software that simultaneously and quickly simulates the material removal process and machine movement while performing interference checking between all relevant components of the machining environment.

Contact Details

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- computer-aided manufacturing ( CAM)

computer-aided manufacturing ( CAM)

Use of computers to control machining and manufacturing processes.

- look-ahead

look-ahead

CNC feature that evaluates many data blocks ahead of the cutting tool’s location to adjust the machining parameters to prevent gouges. This occurs when the feed rate is too high to stop the cutting tool within the required distance, resulting in an overshoot of the tool’s projected path. Ideally, look-ahead should be dynamic, varying the distance and number of program blocks based on the part profile and the desired feed rate.

- numerical control ( NC)

numerical control ( NC)

Any controlled equipment that allows an operator to program its movement by entering a series of coded numbers and symbols. See CNC, computer numerical control; DNC, direct numerical control.

- numerical control ( NC)2

numerical control ( NC)

Any controlled equipment that allows an operator to program its movement by entering a series of coded numbers and symbols. See CNC, computer numerical control; DNC, direct numerical control.