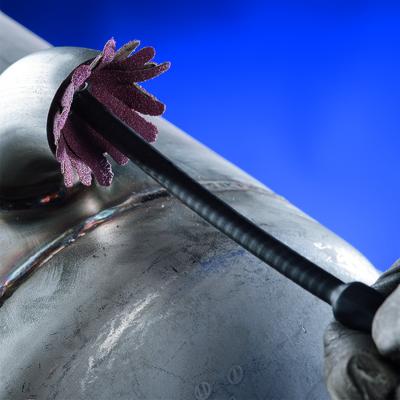

POLISTAR, the line of flexible abrasive stars from PFERD INC. that has been developed for work on the hard-to-reach inner surfaces of bores and pipes, has just gotten even more effective with the introduction of POLISTAR-TUBE. POLISTAR-TUBE is a multi-stage tubing system that highlights the effectiveness of POLISTAR on even more hard to reach bore and pipe interiors. To prevent corrosion on stainless steel pipes, POLISTAR-TUBE is manufactured using stainless steel rivets exclusively.

POLISTAR flexible abrasive stars are particularly well suited for small diameter bores and pipes in the ¼ - 1 ½” dia. range, performing an array of tasks such a cleaning, fine grinding and very fine grinding of bores; removal of heat discoloration in stainless steel after welding; inlet and outlet radiusing of bores; light deburring; and deburring in cross bores. POLISTAR can be stacked in several layers, aligned at an offset from one another so that the abrasive has the optimal effect. It reduces setup times significantly as pads can be changed without removing the arbor from the collet.

POLISTAR-TUBE brings POLISTAR inherent flexibility to the next level. This multi-stage internal fin-grinding system, used with the appropriate

flexible shaft and motor drive, allows the POLISTAR concept to be effective on the most difficult-to-access inner surfaces of pipes, pipe bends and deep bores. Available in a range of diameters and grit sizes, POLISTAR-TUBE is ideal for applications from rough cleaning and deburring up to very fine grinding, with surface finishes up to 8µin. Ra.

In terms of improving working comfort levels, always a key consideration with PFERD, POLISTAR and POLISTAR-TUBE reduce vibration and noise levels during these operations, in a cost effective manner.

Contact Details

Related Glossary Terms

- abrasive

abrasive

Substance used for grinding, honing, lapping, superfinishing and polishing. Examples include garnet, emery, corundum, silicon carbide, cubic boron nitride and diamond in various grit sizes.

- arbor

arbor

Shaft used for rotary support in machining applications. In grinding, the spindle for mounting the wheel; in milling and other cutting operations, the shaft for mounting the cutter.

- collet

collet

Flexible-sided device that secures a tool or workpiece. Similar in function to a chuck, but can accommodate only a narrow size range. Typically provides greater gripping force and precision than a chuck. See chuck.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.