Online CNC Programming Training Courses

Online CNC Programming Training Courses

The technology educators at CamInstructor Inc. announce new, online CNC programming training courses of interest to manufacturers. The course offerings are designed for people brand new to CNC machine tool programming, as well as for more experienced programmers who may need a refresher or get up to speed on the latest software release.

The technology educators at CamInstructor Inc. announce new, online CNC programming training courses of interest to manufacturers. The course offerings are designed for people brand new to CNC machine tool programming, as well as for more experienced programmers who may need a refresher or get up to speed on the latest software release.

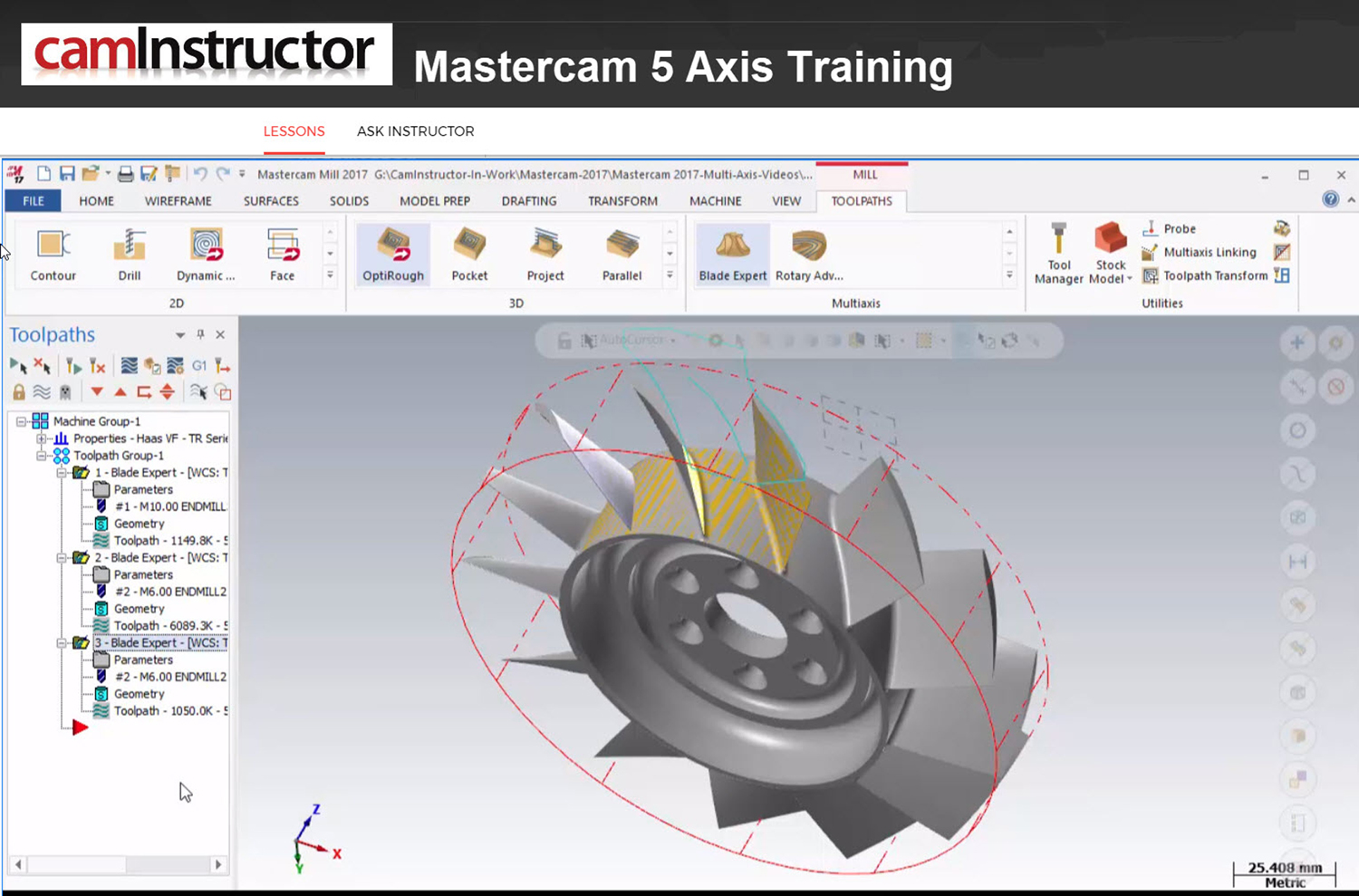

The brand new course "bundle," called CamInstructor Premium, includes comprehensive training in Mastercam CAD/CAM software, SOLIDWORKS CAD software, CNC Programming and instruction on Setting Up and Operating Haas CNC Machines. In addition to the published lessons, there are also videos, quizzes to test comprehension at certain milestones, and access to an instructor for ongoing assistance when questions surface. Further, the "student" has the option to earn a Certificate for certain courses. They also have access to all of the purchased materials for a full year and can download the documents for printing and saving for as long as desired.

"Our customers like so many things about acquiring CNC programming training online," said CamInstructor's Sheila Weidinger. "They enjoy learning at their own pace while they are relaxed and receptive. They don't have to take on the expense or time to be away from the shop for intensive off-site training where 'information overload' can easily happen. They often cite an 80 percent savings in training costs. They appreciate having access to all of the materials for an entire year. And, the interaction with an instructor distinguishes CamInstructor from other online training providers."

In addition to the new CamInstructor Premium bundle, the company also offers a Mastercam Premium bundle and a Mastercam Standard bundle. The Mastercam bundles include Mill 2D, Mill 3D, Lathe, 4-Axis, 5-Axis, Wire and Solids. The Standard Bundle has everything that the Premium Bundle has except the instructor access and testing. CamInstructor has been offering the Mastercam Training Bundles for the past 10 years and have helped train over 2,000 people to learn Mastercam.

"We have several cases in which an employer purchases courses for his employees," said Weidinger. "In those instances, we offer a quantity discount. Some employers offer time for this training on the job site, while others compensate their employees to learn at home. We have included the Mastercam Home Learning Edition for downloading. When an employer makes the purchase, he or she can monitor the employee's progress through the coursework."