Fastems LLC is launching a new generation of flexible manufacturing systems engineered to fulfill manufacturers’ growing needs to handle shorter product life cycles, higher product mixes and lower volumes.

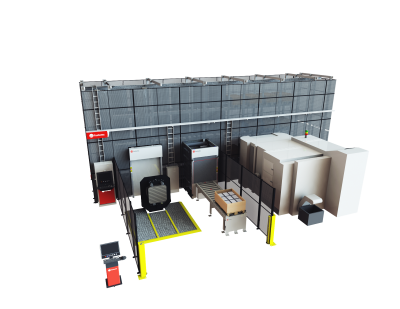

Included in the product family are FMS One (pictured), a fully configurable machine tool pallet automation system, and RoboFMS One, which combines the benefits of an industrial robot and a flexible manufacturing system. Both systems are built from standard modules that offer fast delivery and easy operation. MLS Multi Level Systems and RoboFMS are systems that can be customized for special needs.

The FMSs feature increased modularity that enables fast deployment and adaptability. Standard modules reduce equipment delivery and implementation lead times and enable custom fitting of automation solutions to specific end user needs. Easy integration with a larger number of 4-axis and 5-axis machine tools adds to the hundreds of machine brands already capable of integration with Fastems FMS.

Greater adaptability also includes expanded access to a range of load handlers such as cranes and robots that can handle workpieces from 0.1 kg to 2,500 kg in any shape or size. Smaller shop-floor footprints and more spacious pallet storage maximize space utilization. A key design driver is improved ergonomics, including lower system reaches that free operators from working in difficult positions.

Fastems’ automation equipment includes a variety of extendable and flexible manufacturing systems and robot applications, such as controls; stacker cranes; conveyors; loading/unloading stations; pallet magazines and assembly organizers; and raw material stations. These “open” automation systems can be incorporated with virtually any modern CNC machine tool and auxiliary equipment brands. Typical applications range from joining two machine tools together with a flexible palletized container (FPC) to highly sophisticated, factorywide flexible manufacturing systems.

Contact Details

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- flexible manufacturing system ( FMS)

flexible manufacturing system ( FMS)

Automated manufacturing system designed to machine a variety of similar parts. System is designed to minimize production changeover time. Computers link machine tools with the workhandling system and peripherals. Also associated with machine tools grouped in cells for efficient production. See cell manufacturing.

- flexible manufacturing system ( FMS)2

flexible manufacturing system ( FMS)

Automated manufacturing system designed to machine a variety of similar parts. System is designed to minimize production changeover time. Computers link machine tools with the workhandling system and peripherals. Also associated with machine tools grouped in cells for efficient production. See cell manufacturing.

- industrial robot

industrial robot

Robot designed for industrial use. Primarily used as a material-handling device but also used for changing tools, assembling parts, and manipulating special tools and measuring devices. Depending on design, an industrial robot can be programmed to perform a task by means of a controller, or it can be “walked” through the required movements by utilizing a digitizing system that translates movements into commands that the robot can be “taught.” See robot; teaching pendant.