Model 862 Rotary Encoder with Profibus DP

Model 862 Rotary Encoder with Profibus DP

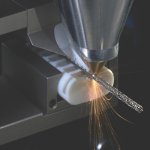

To facilitate the opportunity for machine users to better monitor and implement a predictive motion control system, Leine & Linde introduces a new version of a rotary encoder supporting Condition Monitoring Systems. Called the Model 862 with PROFIBUS DP, this robust mechanical structure from Heidenhain is now a part of Leine & Linde's long history of operation in tough motion control environments, such as seen within the steel, paper and wind power equipment industries, to name a few.

To facilitate the opportunity for machine users to better monitor and implement a predictive motion control system, Leine & Linde introduces a new version of a rotary encoder supporting Condition Monitoring Systems. Called the Model 862 with PROFIBUS DP, this robust mechanical structure from Heidenhain is now a part of Leine & Linde's long history of operation in tough motion control environments, such as seen within the steel, paper and wind power equipment industries, to name a few.

The Leine & Linde Model 862 is a heavy-duty incremental encoder that further enhances plant efficiency by incorporating the PROFIBUS DP communication interface. Leine & Linde's Advanced Diagnostic System (ADS) functionality has been incorporated into the PROFIBUS diagnostic information, giving a plant manager insight on the general health of the encoder, as well as specific failure information should such an event occur.

Working in tandem with the traditional incremental output signals, the PROFIBUS communications can also support velocity feedback, over-speed alarm limits, operating temperature, heartbeat counters, position presets, standstill detection and time, count up direction, internal diagnostics, operating time, and encoder configuration details. While the incremental outputs are supporting, for example, a wind turbine speed control, the PROFIBUS system can be providing the farm operator with higher level information on the overall turbine functionality.

High voltage/high current TTL outputs are provided on the Incremental output channels and the encoder is isolated from the shaft up to 2.5kV. Hybrid ceramic bearings are used to provide this isolation as well as extended operating life. The encoder is rated for operation with a 9 to 30 volt power supply from -40 degrees C to +80 degrees C.

Visual health status for walk-by inspection is also provided via two dual color LEDs integrated into the housing cover. Through combinations of steady and blinking RED/GREEN indicators, encoder power, communication, and operational status can be verified at a glance.