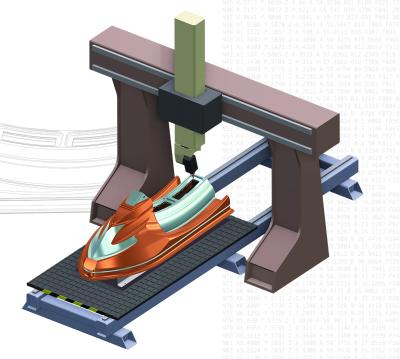

CNC Software announces the release of Mastercam 2018 Router. Mastercam 2018 Router brings a new suite of programming tools focused on delivering speed, automation and efficiency for all machining jobs. Mastercam Router gives your shop the best possible foundation for fast and efficient routing. From general purpose methods, such as optimized nesting and block drilling, to highly specialized toolpaths like 5-axis trimming, Mastercam Router delivers a comprehensive routing package to fit your needs. And, new to this release, Mastercam 2018 for SOLIDWORKS introduces support for Router.

Mastercam for SOLIDWORKS introduces support for Router, including Saw toolpaths, Block Drilling toolpaths, and drawing door and stair geometry. Automatic Toolpathing (ATP) is now available for Mastercam 2018 for SOLIDWORKS. ATP automates the process of assigning toolpaths to geometry for recurrent parts using a machining strategy. Block Drill toolpaths take advantage of the capabilities of a drill block or gang tooling. Use the different drills on the drill block to automatically drill several holes at the same time, or mount different size drills in the block and have Mastercam for SOLIDWORKS drop the proper drill for each hole.

Mastercam Router delivers all the tools you need for precise control over all aspects of 2D machining including Contouring, Drilling, Pocketing, and more. Mastercam also delivers a powerful way to automatically mill and drill solid models—Feature Based Machining. FBM evaluates a part’s features and automatically designs an effective machining strategy.

Mastercam Router gives you a variety of techniques to rough machine all your parts. You can rough cut multiple surfaces, solid models, STL files, or any combination of them. Mastercam’s suite of finishing tools lets you choose the best method for the results you want. And, Mastercam automates leftover material identification and removal, providing you with finer finishes.

In Mastercam Router, you have complete control over toolpath type, tool motion, and tool axis. In addition to general-purpose multiaxis machining, Mastercam also has specialized Add-Ons for multi-bladed parts (Mastercam Blade Expert) and cylinder head ports (Mastercam Port Expert).

Other Mastercam Router Features:

- Complete tab control including Full Tabs and Partial Tabs.

- Mastercam’s standard nesting delivers a fast, efficient, and easily identifiable way of nesting your parts.

- Mastercam’s advanced nesting gives a variety of additional tools, including TrueShape nesting and nesting in scrap material.

- Mastercam’s engraving can give you the effect of classic hand-carved art using your CNC machine.

- Automatic Toolpathing links you to a variety of top design software.

- And much more.

Contact Details

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

- sawing machine ( saw)

sawing machine ( saw)

Machine designed to use a serrated-tooth blade to cut metal or other material. Comes in a wide variety of styles but takes one of four basic forms: hacksaw (a simple, rugged machine that uses a reciprocating motion to part metal or other material); cold or circular saw (powers a circular blade that cuts structural materials); bandsaw (runs an endless band; the two basic types are cutoff and contour band machines, which cut intricate contours and shapes); and abrasive cutoff saw (similar in appearance to the cold saw, but uses an abrasive disc that rotates at high speeds rather than a blade with serrated teeth).

- toolpath( cutter path)

toolpath( cutter path)

2-D or 3-D path generated by program code or a CAM system and followed by tool when machining a part.