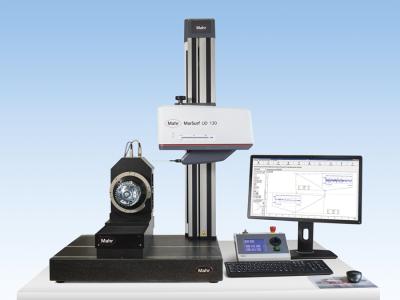

Mahr Federal, Providence, R.I., recently introduced an "entry level" surface finish and contour measuring system capable of generating both surface and contour measurements in a single pass, according to a company news release issued Jan. 21. The MarSurf® UD 130, which replaces the MarSurf UD 120, is said to offer improved nanometer range measurements, high measuring and positioning speeds, a biomimetic probe design with better rigidity and higher dynamics, as well as automatic probe arm recognition.

"We call the MarSurf UD 130 an 'entry level' system because it is a more economical version of our high-end MarSurf LD 130," said Kevin Akin, Mahr Federal's form and surface metrology product manager. "It's designed for applications in industries such as automotive for bearings that require high resolution, but which may not have the very high tolerance requirements of some optical or aerospace applications."

With measuring speeds up to 5mm/sec., the UD 130 is not quite as fast as its LD 130 cousin, but it's still faster than any competitive model, according to the company. The UD 130, which features a traveling length of 130mm, a Z- axis measuring range of up to 20mm and a resolution of 2nm, utilizes an interferometric probe system said to provide better technical data than the inductive probe systems of competitive systems.

Probe movement is registered by photo diodes and evaluated electronically. This innovative measuring method reportedly enables the system to achieve a very high resolution over a large range.

Probe arms are built using a bridge-truss design, which ensures maximum rigidity, reduced vibration and higher dynamics. Different probe tip geometries are available for different measuring tasks. Diamond tips with 2µm and 5µm radii can be used for roughness measurements, and ruby balls or carbide tips with 25µm radii for contour measurements.

The magnetic mounting system allows probes to be changed by hand in seconds, and provides protection in the event of system collision. A ball stop assembly and an embedded electronic chip in the probe arm ensure a repeatable probe mounting position and reliable recognition, respectively. Plus, calibration data is saved, so probe changes do not require additional calibration.

The MarSurf UD 130 comes with Mahr's XCR 20 CNC software package for automatic measurement operation.

Contact Details

Related Glossary Terms

- calibration

calibration

Checking measuring instruments and devices against a master set to ensure that, over time, they have remained dimensionally stable and nominally accurate.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- metrology

metrology

Science of measurement; the principles on which precision machining, quality control and inspection are based. See precision machining, measurement.

- tolerance

tolerance

Minimum and maximum amount a workpiece dimension is allowed to vary from a set standard and still be acceptable.