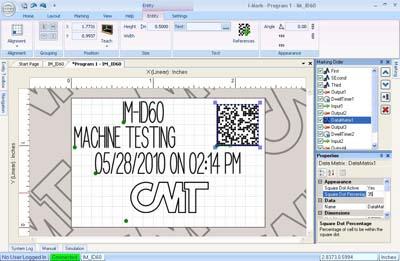

The I-Mark I-Series dot-peen marking system from Columbia Marking Tools comes with marking head, system controller, cables and programming software. The compact head, approximately 7"x7"x", may be mounted on one of three sides. The X-Y CNC movement for the marking head is provided by high-torque stepper motors and linear rails, which mark up to five (1⁄8") characters per second with good-quality readability, according to the company. The I-Mark I-series has the flexibility with it's pneumatic marking pin and carbide tip to inscribe many different materials including ferrous and nonferrous metals. The system controller offers a choice of communications Ethernet IP, Modbus, Serial and I/O and others. Additional drives may be installed to control additional axis or components. I-Mark controllers are offered with an option to control two marking heads. This reportedly allows for a significant savings in machines and installation costs. In addition, the marking controller is capable of providing PLC controls. The required logic is easily programmed in the I-Mark windows platform and downloaded to the controller along the marking information. The I-Mark controller will offer integrators a cost savings to integrators due to the ability to provide marking, motion and additional controls from one control. With this functionality, no additional PLC may be required in an automated marking station. The flexibility of the I-Mark controller extends to it's ability to control other marking systems. The controllers may be programmed and monitored remotely with the use of the I-Mark software. The software has an extensive help file, integrated video demos and graphic icons that combine to provide reduced start-up time. Drag and drop functionality is incorporated to assure quick program generation and easy entity sizing. Multiple character fonts are supported including OCR (optical character recognition). Advanced 2-D data matrix configurations include: entity selection, and sizing parameters. In-depth user control is available for custom shift codes, complex date coding and advanced sequences. Import DXF files for marking logos or for use as background positioning files. The software also contains a machine controller view with advanced diagnostics.

Contact Details

Related Glossary Terms

- 2-D

2-D

Way of displaying real-world objects on a flat surface, showing only height and width. This system uses only the X and Y axes.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.