With the release of HyperConnect, Makino offers a suite of industrial internet of things (IIoT) applications for electrical discharge machines that enhances user experience and efficiency, and reduces machine downtime. Available on all Makino EDMs equipped with Hyper-i control systems, HyperConnect enables shop managers and operators to easily monitor and control EDM processes from any PC, smart device or other Hyper-i control systems on the network.

“EDM operators are already faced with too much on the shop floor. The last thing we want them doing is running back and forth between machines and office spaces,” said Brian Pfluger, EDM product line manager for Makino. “HyperConnect provides these operators with accessibility to everything they need to maximize efficiency, whether they are standing at the machine, sitting in their office or working remotely.”

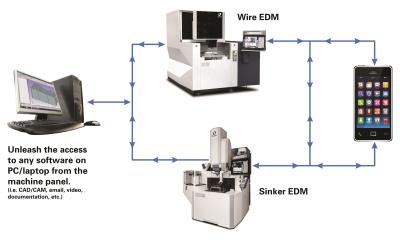

The HyperConnect suite boasts four primary connectivity features for shop personnel to easily monitor, plan and troubleshoot their EDM operations:

- EDM Mail relays machine status information to operators via email during unattended operation to help reduce downtime and support multitasking abilities. It can deliver periodic, timed interval updates of a machine’s operating conditions, or alert operators of a machine stoppage at any hour.

- The Machine Viewer is an application that permits networked access to the Hyper-i control’s NC operation screens, which allows operators to remotely view the machine control and process information from any office environment PC or enabled smart device.

- The Machine-to-Machine Viewer feature gives operators remote access to view and control a networked Hyper-i EDM from another Hyper-i machine, preventing unnecessary foot traffic across the shop floor.

- With the PC Viewer function, operators can achieve greater productivity with remote access to all software on a networked PC directly via the Hyper-i control and includes accessibility to any CAD/CAM software, specialized shop tracking software and Microsoft Office applications.

EDM Mail and PC Viewer functions are the most commonly utilized applications. EDM Mail is used to maximize unattended operation, whereas operators use the PC Viewer to eliminate a substantial amount of non-production motion. The collective capabilities of the HyperConnect communications suite unleash next-level IIoT networking and machine monitoring, and deliver the tools that empower manufacturers with greater flexibility and productivity.

Contact Details

Related Glossary Terms

- electrical-discharge machining ( EDM)

electrical-discharge machining ( EDM)

Process that vaporizes conductive materials by controlled application of pulsed electrical current that flows between a workpiece and electrode (tool) in a dielectric fluid. Permits machining shapes to tight accuracies without the internal stresses conventional machining often generates. Useful in diemaking.

- numerical control ( NC)

numerical control ( NC)

Any controlled equipment that allows an operator to program its movement by entering a series of coded numbers and symbols. See CNC, computer numerical control; DNC, direct numerical control.