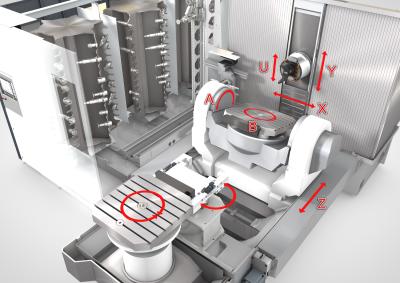

Starrag offers the innovative Heckert DBF 630 6-axis machining center with B over A trunnion table coupled with 45 kW (60 hp)/1,700 Nm (1,254 ft-lb) torque fully integrated U axes head to enable turning, as well as milling, boring, drilling and thread generation operations to be completed in a single setup. OEMs and top-tier suppliers in the oil and gas market, for example, are making significant savings on workpieces such as fluids ends, gate valves, drill bits and pump housings. A perfect example for Starrag´s claim “Engineering precisely what you value.”

The Heckert DBF 630 machining center has 630 mm by 630 mm pallets that can accommodate loads of 1,000 kgs and there is a 40-tool ATC as standard.

The DBF head permits in a single set-up milling, boring, drilling and turning - comprising a faceplate with integrated work spindle and CNC radial facing slide.

For turning on a fixed workpiece, the rotating turning tool, which has an axial runout of just 5 to 6 microns, can be radially adjusted by +/-35 mm. In addition to external, internal and face turning, the head also permits conical and contour turning courtesy of the radial facing slide’s NC axis.

For milling and drilling, the work spindle is arranged in its central position.

Contact Details

Related Glossary Terms

- boring

boring

Enlarging a hole that already has been drilled or cored. Generally, it is an operation of truing the previously drilled hole with a single-point, lathe-type tool. Boring is essentially internal turning, in that usually a single-point cutting tool forms the internal shape. Some tools are available with two cutting edges to balance cutting forces.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- machining center

machining center

CNC machine tool capable of drilling, reaming, tapping, milling and boring. Normally comes with an automatic toolchanger. See automatic toolchanger.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- numerical control ( NC)

numerical control ( NC)

Any controlled equipment that allows an operator to program its movement by entering a series of coded numbers and symbols. See CNC, computer numerical control; DNC, direct numerical control.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.