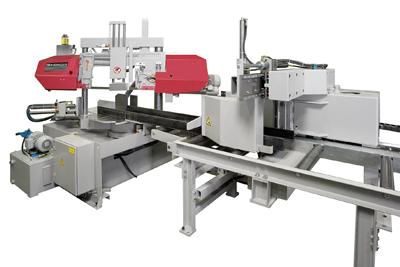

Behringer has launched a new version of its model HBP-310/523G/A mitering bandsaw. The saw now features CNC-dialogue control via PC along with a stand alone 3 meter (118") feeding gripper. A heavy-duty high production machine, the Behringer HBP-310/523G/A automatic horizontal miter bandsaw is designed for accurate and economic cutting of all materials from profiles to high tensile solids, according to the company.

The new PC computer interface enables total control over mitering functions while at the same time permitting the machine operator to attend to other important tasks. The PC supplied by Behringer runs on MS Windows. The display is a 15-inch flat panel LCD (1024x768). Keypad or touch screen commands facilitate fast, accurate programming and execution of sawing operations.

"The PC-based control system enables data sharing with key personnel," said Joe Suydam, Behringer Sales and Marketing Associate. "This includes sophisticated machine commands, not just stop and go. For example, there is an auto-feed control with electronic adjustment of the blade speed and downfeed rate based on the selected material grade and cutting width." Suydam said that the remote CNC programming capabilities include a broad range of commands including input of orders with material number, part dimensions, cut-off lengths, quantity, trim cut length, part number and drawing number. Input is stored in the job data bank and can be re-called at any time.

A particularly useful feature of the new PC controlled saw is a program which tracks saw band deflection to monitor the straightness of the cut. Regardless of where the operator is, real-time digital display of blade deviation from the zero line may be viewed on the PC screen. When a preset deflection limit value is reached, the feed rate is automatically reduced. After 30 seconds, if the blade deflection is still over limit, the saw automatically executes another reduction of the feed rate. When the blade deflection no longer triggers reductions to feed rate, the machine readjusts to initial feed rate settings. Should blade deflection continue to increase, the saw blade will withdraw from the cut, the machine will switch off and an alarm will appear on the operator's PC screen.

The HBP-310/523G/A saw is mounted on a massive steel base with integrated swivel permitting rotation of the bowframe to any angle between 45 degrees-right through 60 degrees-left off of 90 degrees making the total miter range 105 degrees. The cutting angle is displayed digitally. Cast iron construction gives the saw frame the rigidity needed to reduce vibrations during cutting and enable high band tensioning. The vibration dampening Behringer design also facilitates precision movement of the blade and results in tight tolerances. The machine utilizes positive hydraulic downfeed with a heavy-duty gearbox and a 5.4 HP motor.

The saw frame is inclined 3 degrees to optimize the number of blade teeth which contact the material being cut. This saves time by minimizing the cutting cycle time for all types of stock including profiles and bundles. Like other Behringer bandsaws, the HBP-310/523G/A miter saw dual column frame design enhances torsion resistance during cutting. This design also provides controlled application of downfeed power resulting in precise, flat cuts and tight tolerances.

The 3 meter (118") feed gripper can dramatically reduce cycle time particularly when cutting longer pieces. For example, if the desired cut length is 52" long, the gripper will feed forward 52", make a cut, and feed forward again 52" to make a second cut before retracting to the beginning of the stroke. The feed cycle time is thereby reduced helping to promote a higher throughput. This is also an advantage when cutting shorter pieces. The feeding gripper will incrementally move to the specified cut length until the cut length is no longer possible by the gripper and then retract to the beginning of the stroke. The motorized feed gripper unit rides on linear bearings assuring smooth, accurate movement. The feed length measuring is by rack and pinion and NC programming.

As the bowframe of the saw rotates to the programmed miter angle, the feeding gripper advances the material to the desired cut length. This reduces cycle times and increases production. Hydraulic clamps hold the saw frame in position and digital display of the cutting angle appears on the operator's control panel. The bowframe rotation point is directly beneath the blade, in line with the fixed vise jaw. The material remains in a single plane which eliminates the need for additional material handling. The vise, therefore, does not need to be repositioned to clamp material when cutting different angles.

With a swivel range of 237 inches, the saw will cut miters of 75, 60, 45 and 30 degrees. Cutting capacity for round stock is from 0.39 to 12.2 inches. For rectangular stock the saw handles from 0.78-inch square to 20.4 x 12.2 inches.

Contact Details

Related Glossary Terms

- bandsaw

bandsaw

Machine that utilizes an endless band, normally with serrated teeth, for cutoff or contour sawing. See saw, sawing machine.

- bandsaw blade ( band)

bandsaw blade ( band)

Endless band, normally with serrated teeth, that serves as the cutting tool for cutoff or contour band machines.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- flat ( screw flat)

flat ( screw flat)

Flat surface machined into the shank of a cutting tool for enhanced holding of the tool.

- numerical control ( NC)

numerical control ( NC)

Any controlled equipment that allows an operator to program its movement by entering a series of coded numbers and symbols. See CNC, computer numerical control; DNC, direct numerical control.

- sawing

sawing

Machining operation in which a powered machine, usually equipped with a blade having milled or ground teeth, is used to part material (cutoff) or give it a new shape (contour bandsawing, band machining). Four basic types of sawing operations are: hacksawing (power or manual operation in which the blade moves back and forth through the work, cutting on one of the strokes); cold or circular sawing (a rotating, circular, toothed blade parts the material much as a workshop table saw or radial-arm saw cuts wood); bandsawing (a flexible, toothed blade rides on wheels under tension and is guided through the work); and abrasive sawing (abrasive points attached to a fiber or metal backing part stock, could be considered a grinding operation).

- sawing machine ( saw)

sawing machine ( saw)

Machine designed to use a serrated-tooth blade to cut metal or other material. Comes in a wide variety of styles but takes one of four basic forms: hacksaw (a simple, rugged machine that uses a reciprocating motion to part metal or other material); cold or circular saw (powers a circular blade that cuts structural materials); bandsaw (runs an endless band; the two basic types are cutoff and contour band machines, which cut intricate contours and shapes); and abrasive cutoff saw (similar in appearance to the cold saw, but uses an abrasive disc that rotates at high speeds rather than a blade with serrated teeth).