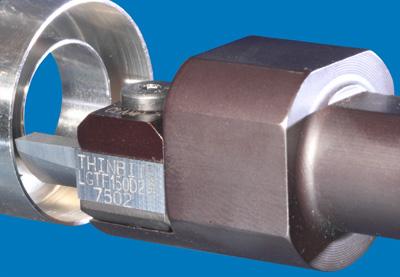

THINBIT, manufactured by Kaiser Tool Co., is pleased to announce the expansion of the GROOVE'N TURN line with right-hand, counterclockwise face grooving inserts. These new tools are designed to cut internal face grooves with major diameters starting at 0.300".

The inserts are available in 0.004" through 0.150" in 0.001" increments with sharp corner through full radius options. Major diameters are offered in 0.300", 0.750", 1.250" and 3.000". These inserts are made from sub-micron grain carbide with grades for ferrous and nonferrous materials either uncoated or with TiN, TiCN, TiAIN or diamond film coatings.

GROOVE'N TURN inserts can be used in conventional, Swiss and CNC machines. Toolholders are available in square shank sizes 5/16" through 1-¼" and round shank sizes ½" through 1" with straight and 90o presentations. The inserts fit all "L" series toolholders. Modifications can be provided on any THINBIT tooling.

Contact Details

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- grooving

grooving

Machining grooves and shallow channels. Example: grooving ball-bearing raceways. Typically performed by tools that are capable of light cuts at high feed rates. Imparts high-quality finish.

- shank

shank

Main body of a tool; the portion of a drill or similar end-held tool that fits into a collet, chuck or similar mounting device.

- titanium carbonitride ( TiCN)

titanium carbonitride ( TiCN)

Often used as a tool coating. See coated tools.

- titanium nitride ( TiN)

titanium nitride ( TiN)

Added to titanium-carbide tooling to permit machining of hard metals at high speeds. Also used as a tool coating. See coated tools.