FANUC America Corp. introduces FASBacCNC (FOCAS Automation Solution Backup CNC), a network based backup solution for FANUC CNCs. FASBacCNC eliminates the risk of one of the most common and expensive service interventions: extended downtime as a result of the loss of critical files on the CNC following a hardware failure or operational mistake.

FASBacCNC provides peace of mind by automatically backing up the CNC files that have been created and customized by the machine tool builder or end user to a remote network server. Files backed up can include CNC parameters, PMC ladder and parameters, custom macros and variables, part programs, tool offsets and workpiece coordinate system offsets.

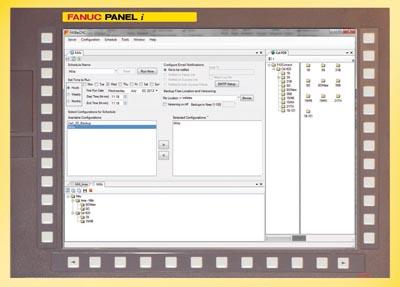

FASBacCNC is a front end application that interfaces with FANUC's FASConnect server for file browsing, scheduling and backup operations for FOCAS enabled FANUC CNCs. FASBacCNC can work with multiple FASConnect servers across an entire network, so that files from a single machine, work cell, factory or even multiple factories can be combined into a single configuration for backup scheduling. FASBacCNC can be used on any personal computer on the network located out in the factory, back in an office or from a remote location.

Users browse their FASConnect servers with easy to use drag and drop navigation. Individual files can be uploaded manually or multiple files from multiple CNCs across the network can be included in a configuration. Multiple configurations can then be combined into a single scheduled backup. Powerful and flexible scheduling allows automatic backup to be executed hourly, daily, weekly or monthly. Users may also execute schedules manually for immediate needs. Users receive email notifications relating to the scheduled backup status.

Contact Details

Related Glossary Terms

- backing

backing

1. Flexible portion of a bandsaw blade. 2. Support material behind the cutting edge of a tool. 3. Base material for coated abrasives.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.