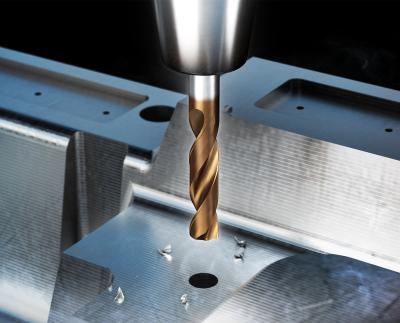

YG-1 has beefed up its successful DREAM DRILLS® line-up with the new DREAM DRILLS PRO line optimized for machining in steel and cast iron, the company announced recently.

“The main advantage of this new DREAM DRILLS PRO line is high cutting speeds with longer tool life,” said Steve Pilger, Product Manager, Holemaking. “Our engineers developed several advances that combine to make these tools faster, more efficient and longer lasting than other comparable tools tested.”

New DREAM DRILLS PRO tools are made with micrograin carbide for exceptional core strength and longer tool life. They also feature YG-1’s unique, wave-shaped cutting edge to reduce cutting forces, and an advanced, wide-flute design optimized for faster, reliable chip evacuation. A self-centering 140° point angle reduces torque and extends tool life.

YG-1’s special Z-Coating (silicon-based, nano-layered) technology gives cutting edges extremely high hardness and greater heat resistance to keep cutting and finishing long after competing brands have called it quits. The resulting higher machining efficiency means superior surface finishes and more parts per tool. (See attached for test data.)

DREAM DRILLS PRO tools come in drilling depths of 3xD to 5xD, in sizes from Ø1 to Ø20.

DREAM DRILLS PRO is the latest line in the DREAM DRILLS product matrix from YG-1, including General Purpose, MQL, HIGH FEED, FLAT BOTTOM, ALU®, HIGH HARDENED and INOX®. Each aligns with customers’ various machining demands and applications.

Contact Details

Related Glossary Terms

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- flat ( screw flat)

flat ( screw flat)

Flat surface machined into the shank of a cutting tool for enhanced holding of the tool.

- hardness

hardness

Hardness is a measure of the resistance of a material to surface indentation or abrasion. There is no absolute scale for hardness. In order to express hardness quantitatively, each type of test has its own scale, which defines hardness. Indentation hardness obtained through static methods is measured by Brinell, Rockwell, Vickers and Knoop tests. Hardness without indentation is measured by a dynamic method, known as the Scleroscope test.

- point angle

point angle

Included angle at the point of a twist drill or similar tool; for general-purpose tools, the point angle is typically 118°.