As manufacturing plants struggle to meet demand due to industry-wide challenges, workers are looking for revolutionary yet easy-to-implement tools that can elicit a ripple effect of positive, efficiency-enhancing changes.

For the workholding industry in particular, the Adaptix Soft Jaw could be one of these tools.

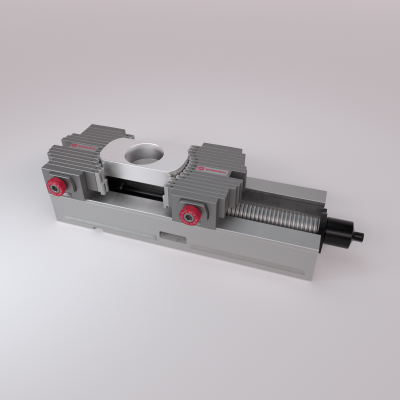

Engineered by IMI Precision Engineering’s new Norgren Workholding group, Adaptix is a malleable soft jaw that uses adjustable fingers and interchangeable tips to grip uniquely shaped parts. Because Adaptix can be adjusted, locked in place, and reset in a matter of minutes, machinists using this tool no longer need to manufacture single-application aluminum soft jaws before milling each new part.

Adaptix has the potential to save countless resources throughout the computer numerical control (CNC) machining workflow including time, raw materials like aluminum, and storage space that would otherwise be devoted to single-application soft jaws. Truly one part with infinite possibilities, Adaptix can help establish a safer, more efficient, and more sustainable operating model for a 21st century machining industry.

The Adaptix™ Soft Jaw uses adjustable fingers and interchangeable tips to grip a wide variety of parts or workpieces during the computer numerical control (CNC) machining process. It was specially engineered to be a one-size-fits-all alternative to standard, single-application aluminum soft jaws.

“Single-application soft jaws require a significant amount of time, skill and raw material to construct, even before a single part is milled,” said Tom Wood, Senior Director of Growth Initiatives at Norgren. “We saw an opportunity to solve several machining problems with just one tool, and so we designed the Adaptix™ Soft Jaw to grip nearly any part with comparable repeatability and clamping force as single-application soft jaws. This singular innovation in the CNC machining workflow can have a huge impact on several pain points in the industry.”

The Adaptix™ Soft Jaw’s adjustable fingers and interchangeable tips are made out of a variety of different materials to match the milling needs of a particular part. The fingers easily mold into place to conform to the shape of the target part and then are locked in place. This configuration process takes minutes, instead of hours, on average, with traditional soft jaws. The soft jaw fits directly onto a vise, and is currently compatible with Kurt and Schunk brand vises, with other vise compatibility planned in the near future.

“The COVID-19 pandemic and the pressure it placed on supply chains, hiring needs, and skills training only exacerbated the existing needs of the machining industry,” said Wood. “Adaptix™ and, by extension, Norgren Workholding were created by Norgren to leverage our commitment to breakthrough engineering to make manufacturing more streamlined and accessible, and to solve several industry bottlenecks.”

Contact Details

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- computer numerical control ( CNC)2

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- numerical control ( NC)

numerical control ( NC)

Any controlled equipment that allows an operator to program its movement by entering a series of coded numbers and symbols. See CNC, computer numerical control; DNC, direct numerical control.

- sawing machine ( saw)

sawing machine ( saw)

Machine designed to use a serrated-tooth blade to cut metal or other material. Comes in a wide variety of styles but takes one of four basic forms: hacksaw (a simple, rugged machine that uses a reciprocating motion to part metal or other material); cold or circular saw (powers a circular blade that cuts structural materials); bandsaw (runs an endless band; the two basic types are cutoff and contour band machines, which cut intricate contours and shapes); and abrasive cutoff saw (similar in appearance to the cold saw, but uses an abrasive disc that rotates at high speeds rather than a blade with serrated teeth).