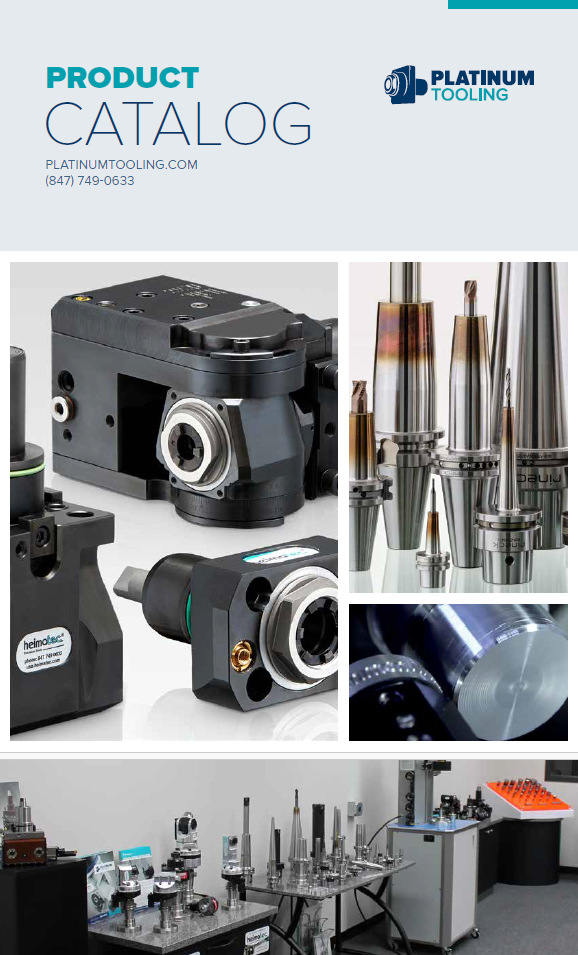

Platinum Tooling, the importer and master distributor of live tools, angle heads, Swiss machine products, knurling and marking tools manufactured by various international suppliers, just announced the release of their new product catalog.

The company’s premium lines include live tools and angle heads from Heimatec, Swiss-type collets/guide bushings from Tecnicrafts, mechanical, air and motor spindles from Henninger and QUICK knurling and marking tools from Hommel + Keller. Additional products are shrink-fit tool holders and machines from Rineck, specialty and adaptive guide bushings from Dunner and broaching tools from REV.

Manufacturing tools for the most popular machine tool builders, Heimatec supplies precision live and static tools in all sizes, ranging from the smallest Swiss-type CNC lathes to the largest live tool lathes. Their angle heads are manufactured to handle the most difficult applications; hence, they are ideal for drilling, tapping and milling operations.

Tecnicrafts Swiss-type collets and guide bushings are available in standard and ultra-precision grades with a runout accuracy of 5 microns or less. Bore profiles include round, square, hexagon, rectangle and custom. Guide bushings are chamfered in the back bore and slit to provide smooth guiding and unwanted marks.

Available as air, mechanical spindle and high frequency motor, Henninger speed increasers help maximize productivity by achieving a higher cutting tool rpm that is required for certain applications in today’s marketplace.

The Hommel + Keller QUICK line offers premium quality knurling and marking tools with special consideration for customer requirements. For both form knurling and cut knurling, QUICK fulfills the most stringent quality standards and masters difficult tasks, while marking tools make it possible to mark workpieces in seconds on a variety of surfaces and part geometries.

Rineck offers standard and custom shrink-fit tool holders with various connections including CAT, HSK, BT, SK, PSC and straight shank extensions. Rineck shrink-fit machines are equipped with an elevation cooling system. Heated tools can be moved to a cooling tank with the push of a button. The machine’s smart design keeps accessories stored but close at hand during operation.

A manufacturer of guide bushings for Swiss-type CNC lathes, Dunner manufactures bronze, ceramic and titane (Meehanite®) guide bushings for customer machining needs. All guide bushings are ready for machine use with finished internal surfaces and geometries designed to offer the best result with nominal size material.

REV broaching tools are ideal for machining simple keyways or internal and external profiles, both teeth and splines. Common profiles, including square and hexagon, are easily achieved and custom profiles are available.

Contact Details

Related Glossary Terms

- broaching

broaching

Operation in which a cutter progressively enlarges a slot or hole or shapes a workpiece exterior. Low teeth start the cut, intermediate teeth remove the majority of the material and high teeth finish the task. Broaching can be a one-step operation, as opposed to milling and slotting, which require repeated passes. Typically, however, broaching also involves multiple passes.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- knurling

knurling

Chipless material-displacement process that is usually accomplished on a lathe by forcing a knurling die into the surface of a rotating workpiece to create a pattern. Knurling is often performed to create a decorative or gripping surface and repair undersized shafts.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- shank

shank

Main body of a tool; the portion of a drill or similar end-held tool that fits into a collet, chuck or similar mounting device.

- tapping

tapping

Machining operation in which a tap, with teeth on its periphery, cuts internal threads in a predrilled hole having a smaller diameter than the tap diameter. Threads are formed by a combined rotary and axial-relative motion between tap and workpiece. See tap.