ANCA CNC Machines, a leader in CNC grinding technology, has opened its #ANCATooloftheYear2025 awards. This prestigious competition invites toolmakers from around the world to showcase their outstanding designs, precision, and craftsmanship.

Participants will compete for an array of prizes, including AUD$ 10,000 in ANCA products, a trip to ANCA Australia or Thailand, an on-site consultation with ANCA experts, and a 12-month ANCA Academy subscription for professional development.

Participants can enter one or both of the following categories: #MadeonANCA for physical tools created using ANCA technology, and Most Innovative Tool Design for virtual tools that showcase cutting-edge creativity.

The winner of #MadeonANCA receives:

- Option 1: AUD$ 10,000 in ANCA accessories/software + a trip to ANCA Australia or Thailand

- Option 2: An on-site consultation with an ANCA Application Engineer to optimise cycle times and boost productivity

The winner of Most Innovative Tool Design receives:

- A 12-month subscription to ANCA Academy, ANCA’s e-learning platform, for five people

“At ANCA, we develop and continuously improve our machines and software. Our customers create incredible products through their skill and innovation in applying ANCA technology. We see #ANCATooloftheYear2025 and the Female Machinist Award as a spotlight on the trailblazers who are applying their knowledge to create something unique in the market. Having celebrated 50 years of innovation last year, we now look firmly ahead to a future driven by bold ideas, precision craftsmanship, and talented individuals,” said Patrick Boland, ANCA Co-Founder.

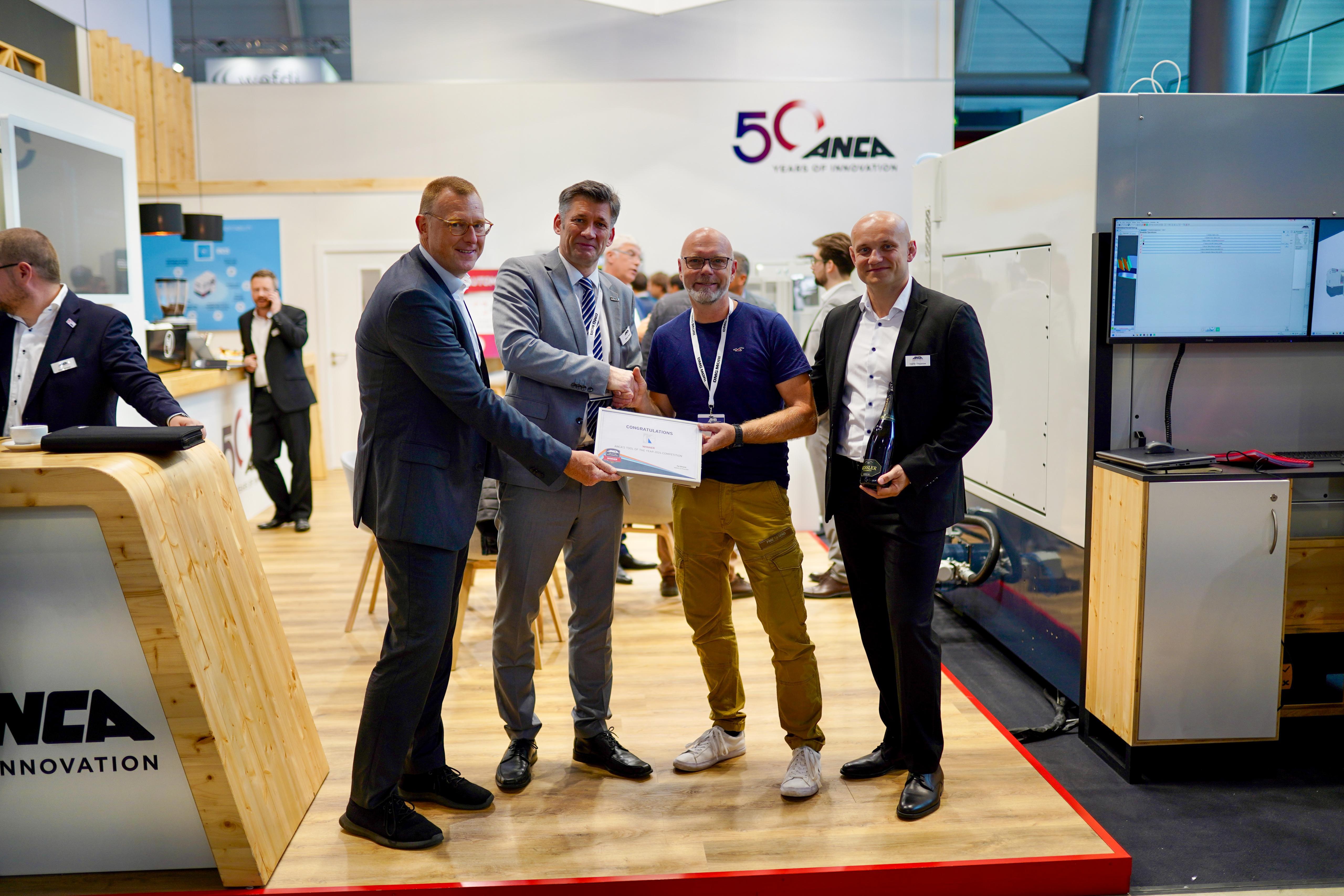

Submissions are open until July 21, 2025. Winners will be announced at EMO 2025 in Hannover.

Enter now at www.anca.com/Tool-of-the-Year

Female Machinist Award 2025

ANCA’s Female Machinist Award returns in 2025, which recognises the outstanding achievements of women in the tool and cutter grinding industry. This award celebrates the growing role of women in manufacturing and their contribution to advancing the cutting tool industry.

ANCA’s Female Machinist Award returns in 2025, which recognises the outstanding achievements of women in the tool and cutter grinding industry. This award celebrates the growing role of women in manufacturing and their contribution to advancing the cutting tool industry.

Jennifer Baldus, Managing Director at Spreyer-Werkzeugtechnik GmbH in Limburg and member of the judging panel, said: “For 50 years, Spreyer has stood for precision and high performance in the tool industry. Our success has always been down to committed and talented people, both men and women. Today, I experience this in my daily dialogue with customers: Women are more in demand in our industry than ever before. The 'Female Machinist of the Year' competition puts the spotlight on the outstanding achievements of female precision tool grinders, creates important role models, and encourages young talents to make their way in this demanding and fascinating profession.”

Women of all skill levels who are actively using ANCA technology in their work are encouraged to apply. Submissions will be evaluated based on exceptional problem-solving skills to overcome challenges, innovative and effective tool design, and the demonstrated ability to think critically and develop innovative solutions.

The winner of the Female Machinist Award receives:

• A fully funded ticket to attend a major trade show where ANCA is exhibiting

• Exclusive access to ANCA’s leadership, engineers, and product experts

• Networking opportunities with industry professionals and access to educational seminars and workshops

Enter now at www.anca.com/Female-Machinist-Award

Contact Details

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.