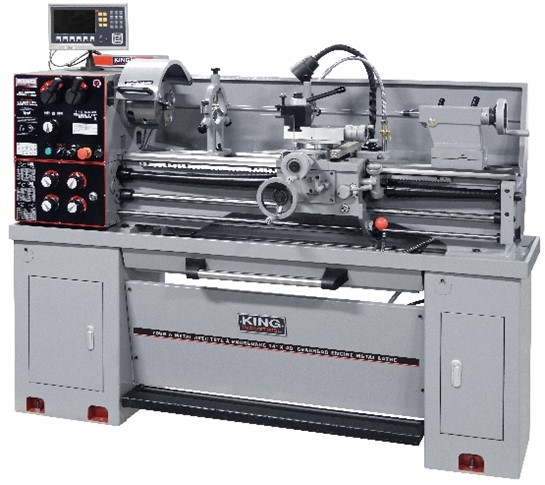

KING KC-1440ML-2 14×40 Lathe

KING KC-1440ML-2 14×40 Lathe

KBC Tools & Machinery announced that the KING KC-1440ML-2 14x40 lathe with a digital readout (DRO).

KBC Tools & Machinery announced that the KING KC-1440ML-2 14x40 lathe with a digital readout (DRO) is now available for immediate purchase at the company's Mississauga, Ontario, Canada, showroom.

The lathe comes factory-installed with the fully functional 2-axis (X, Y) digital readout (DRO).

Ted Fuller, vice president of King Canada, said, "In turning and machining, accuracy is paramount. Now the best in metal lathes comes with the best in Digital Read-Out (DRO) precision. Intelligent calibration is a vital element to repeatable precision, and it is now included at a great price. Everything you asked for in a complete turning package."

Fuller added that with the KC-1440ML-2, simply learn how to use the DRO and start machining. The setup is intuitive, and the machine is easy to operate – exactly what every machinist wants. We all know the headaches of bunging up a scale or adding unnecessary holes when installing a DRO.

Fuller added that with the KC-1440ML-2, simply learn how to use the DRO and start machining. The setup is intuitive, and the machine is easy to operate – exactly what every machinist wants. We all know the headaches of bunging up a scale or adding unnecessary holes when installing a DRO.

Key Features:

- 2-hp motor for high-performance cutting

- 2" spindle bore capacity for versatility

- Factory-installed Digital Readout (DRO) – saves time and money, fully functional out of the box!

- No installation needed – just power up, learn how to use the machine and DRO, and start working

- Safety guard with limit switch protection

- Completely equipped: 7"-3 jaw chuck, 8"-4 jaw chuck, quick-change tool posts, steady rest, follow rest, D1-5 camlock faceplate, coolant system, and thread chasing dial indicator.

- CSA approved – eliminates electrical work or installation issues

The KING KC-1440ML-2 is the only unit available in Canada. KING's official release is later this month, with stock expected to arrive in June.