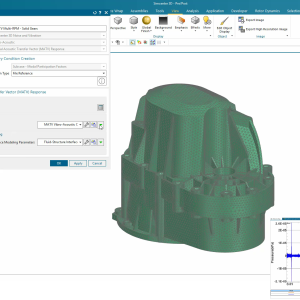

Software

CGTech's Vericut Force software extends cutting tool life

CGTech Inc.’s Vericut Force extends cutting tool life by using a manufacturer’s recommended cutting parameters to optimize NC programs, keeping chip thickness maximized and constant. At the same time, Force limits feed rates, force and deflection to ensure that cutting tools are utilized safely to their full potential in any given cut.

CGTech Inc. | www.cgtech.com