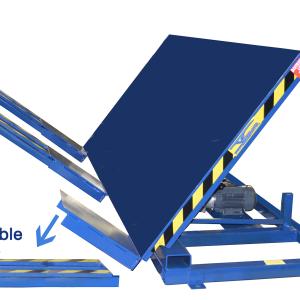

Parts Handling

Outpace the Competition with Okuma Automation Solutions

Searching for skilled labor and ways to increase overall efficiency and productivity has just gotten much easier with Okuma’s automation solutions. Whether you’re looking to integrate automation on your existing machine or need a machine that comes fully equipped, Okuma can help you outpace the competition by using state-of-the-art technology. Automation solution options include automatic tool changers, automatic pallet changers, gantry loaders, external conveyor belts and robotic cells. Learn more about Okuma’s automation solutions in this video.