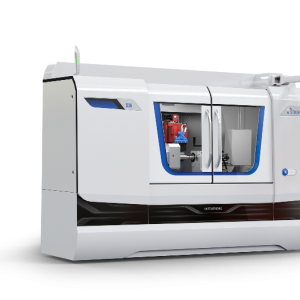

Precision Grinding Packed With Features

The IG 282 SD rotary surface grinder is packed with innovative features making it more powerful, precise, and most importantly, even easier to use. This machine is the first DCM style rotary surface grinder to feature a precision servo drive cross slide motor that allows this machine to grind tight tolerances along both the Z and X axis. Perform precise step grinds in materials such as glass, ceramic, carbide, and metals. Contact DCM and ask about our new features such as automatic part detection and automation compatibility.