Visual Components: If it ‘ain’t broke,’ you still might need to ‘fix it’

Visual Components: If it ‘ain’t broke,’ you still might need to ‘fix it’

The old adage is that if it "ain't broke, don't fix it." While this has been tried and true wisdom for ages, it might be a little suspect in today's modern age, when one technology advantage can make the difference between standing apart from the competition or falling behind. That is one of the observations imparted by Visual Components, which at the recent Fabtech Show in Chicago gave Cutting Tool Engineering a "walk-through" of its newly released, highly anticipated, Visual Components 5.0 software platform.

The old adage is that if it "ain't broke, don't fix it." While this has been tried-and-true wisdom for ages, it might be a little suspect in today's modern age, when one technology advantage can make the difference between standing apart from the competition or falling behind.

That is one of the observations imparted by Visual Components, which at the recent Fabtech Show in Chicago gave Cutting Tool Engineering a "walk through" of its newly released, highly anticipated, Visual Components 5.0 software platform.

"The [5.0 version] is an offline programming and a discrete event tool that can be used by any manufacturer looking to improve their current process," explained Graham Wloch, director of business development at Visual Components. "Times change, challenges change, technology changes; you really need to be on that cutting edge. You need to be taking advantage of all the tools that are available to you."

Because Visual Components supports all major robot brands — data from 70 robot manufacturers is currently embedded in its CAD-agnostic software — the new platform offers flexibility without locking users into specific hardware. Teams can standardize their automation processes across mixed robot fleets—whether they're just beginning with robotics or scaling up existing operations.

This ability to evolve and change with the times and technologies is critical, he said. Especially during these times when skilled labor is in such high demand.

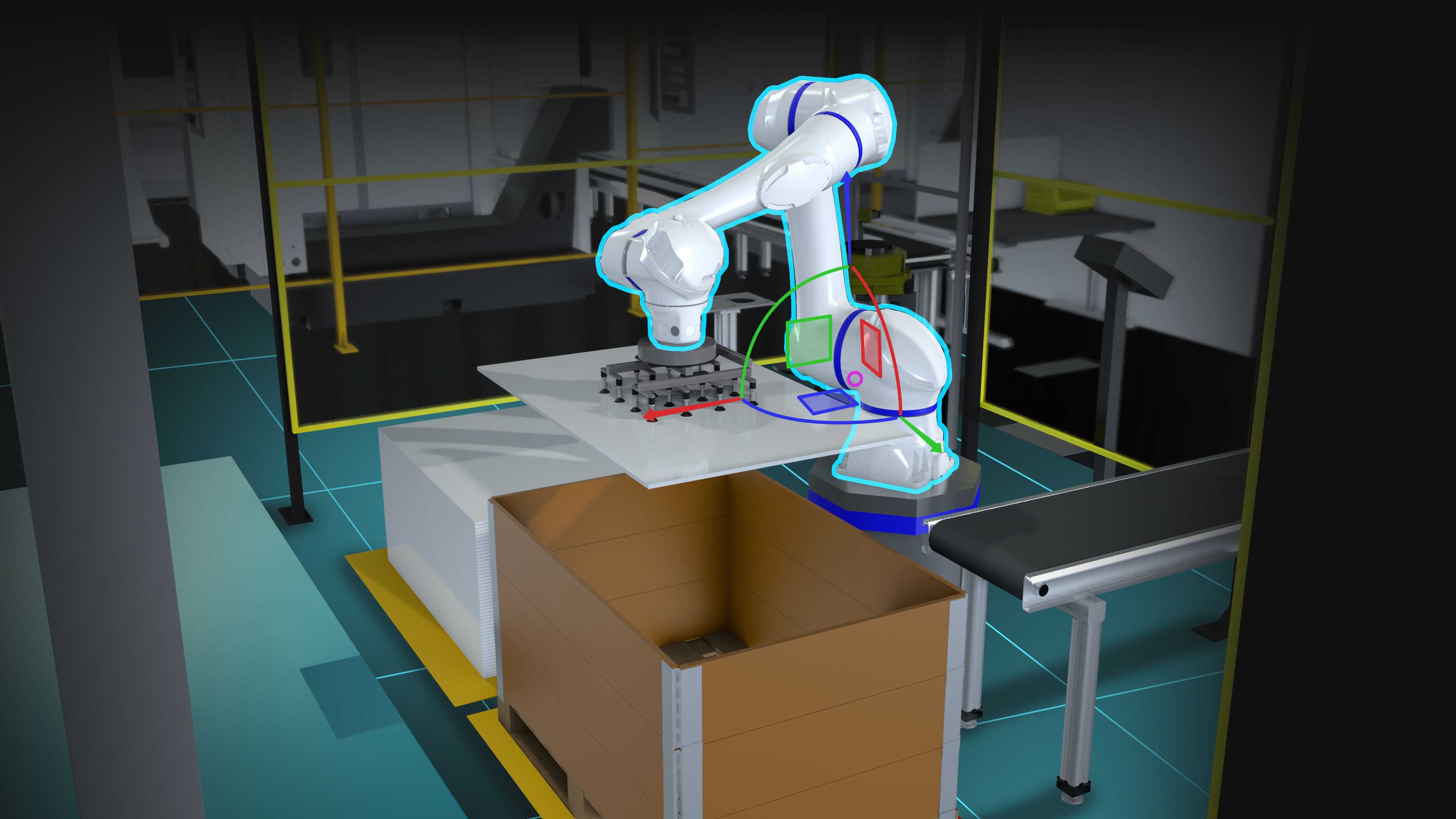

Visual Components 5.0 introduces new features for its robot motion controller, enhancing robot offline programming (OLP) by providing faster, more intuitive control and direct compatibility with robot controllers. ">

Visual Components 5.0 introduces new features for its robot motion controller, enhancing robot offline programming (OLP) by providing faster, more intuitive control and direct compatibility with robot controllers. ">"Automation does not come in and eliminate workers. It really lets you take those skilled workers and put them in the right places," he explained. "It allows it to be a force multiplier. It allows you to improve multiple processes at the same time by being efficient. not only in up 10, but up 20, up 30, up 40, and all the way down the

line. It doesn't really matter what your industry is. It doesn't really matter what you're producing; simulation is a great tool to be able to understand everything, where the biggest ROI is. That bang for the buck is huge today. By being able to take a step back, by being able to do it offline, by being able to do all of those different things through simulation, you absolutely get a better process and a better product."

Visual Components 5.0 refines digital manufacturing workflows through a unified platform for layout design, process simulation and virtual commissioning, Wloch explained. The upgraded end-to-end simulation capabilities are complemented by the "most advanced level of OLP automation to date." Now, manufacturers can fully leverage model-based engineering from the earliest stages of production planning to final execution. Visual Components 5.0 supports model-based definition and product manufacturing information in one environment with compatibility across multiple brands. In turn, vital data is extracted directly from current CAD files for the robotic program.

Wloch told Cutting Tool Engineering that the new version provides manufacturers with the ability to have a bigger, more complete picture of their process, not just how one cell operates, not just how one process can be better, but how everything can be improved. This includes incorporating everyone working through the steps of digital production planning from engineers, production floor managers, CEOs; which "increases the clarity of the process and confidence in the results."

The new platform also supports modern scripting with a variety of programs, which gives its users the ability to tailor simulations, automate repetitive tasks and work with widely used libraries, he said. Connectivity supports real-time simulation data across multiple hardware and robot systems. Included in the software are specs from 70 different robot manufacturers, Wloch said. In the fully digital phase, advanced features like collision detection and adaptive path solving come into play. The software identifies potential clashes and ensures robot motion is both safe and efficient.

"I love saying it; It's not big companies that eat small companies anymore. It's the fast companies that eat the slow companies. If you're not changing, if you're not on that cutting edge, if you're not, again, taking advantage of all those tools out there, you might wake up one day and be technically irrelevant."