OMAX showcases the next-gen in water jet machining at Fabtech

OMAX showcases the next-gen in water jet machining at Fabtech

Steve Ulmer, director of sales for OMAX Corp., provided Cutting Tool Engineering with a look at two of OMAX's latest generations of equipment during September's Fabtech show. The machines included the new Maxiem 1530X water jet machine and the ProtoMax compact water jet. The 1530X is the next generation in water jet machining, and it's an upgrade from the Maxiem product that was released over 10 years ago. It features a completely new design with more rigid uprights, more rigid axis on the X and the Y, greater bed capacity and greater flexibility with what is in the tank. ProtoMax is a compact water jet that can be used where it is needed. All the mobile water jet requires is single-phase power, and access to water and a drain, and you can be cutting parts.

Waterjets with a large cutting area and a diamond-integrated nozzle that allows for a wide range of materials, or a compact and mobile waterjet that allows users to start cutting anywhere in any place. If you were at Fabtech you could have had a chance to take a close-up look at both types of machines and made the choice for yourself.

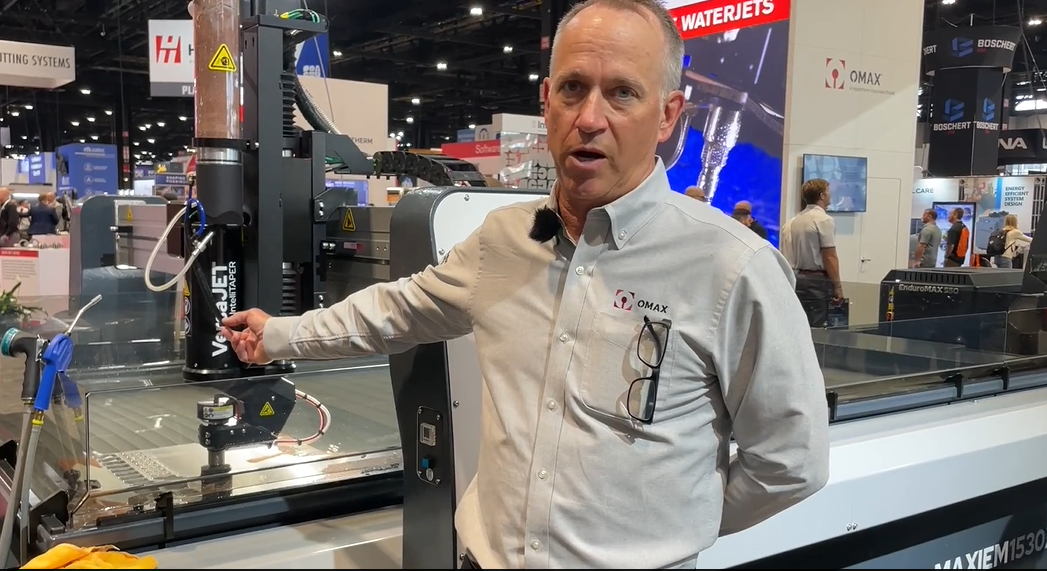

Steve Ulmer, director of sales for OMAX Corporation and Hypertherm, provided Cutting Tool Engineering with a look at two of OMAX's latest generations of equipment during September's Fabtech show. The machines included the new Maxiem 1530X water jet machine and the ProtoMax compact water jet.

The new Maxiem 1530X is the next generation in water jet machining, and it's an upgrade from the Maxiem product the company released over 10 years ago.

"It's a completely new design with more rigid uprights, more rigid axis on the X and the Y, greater bed capacity, and greater flexibility with what we have in the tank," said Ulmer.

The machine at the show was equipped with the VersaJet cutting nozzle with a range of degrees for 5-axis cutting of beveled edges, angled sides, countersinks, and 3D shapes. Fully software-controlled, VersaJet virtually eliminates taper on finished parts with automatic taper compensation.

"The VersaJet you see right here," said Ulmer, referring to the water cutting machine, "offers both taper-free cutting and high-angled cutting up to 60 degrees."

He added that the Maxiem 1530X now features clog detection. One challenge to water jet cutting is the potential for clog, he said. "What this is going to do is tell you when the abrasive's clog, and pause the machine so you can set it."

The machine was using OMAX's IntelliMAX Software Suite premium software embedded into the system. "It's going to offer 40 % faster cutting over the older system with no change to the pump, no change the electricity, just in the software alone. Some of the parts that we're cutting accuracy up to 5,000th, angled cutting, and those are being cut right here right at the show. So truly with this machine, we feel like the best just got better with the new OMAX 1530."

Compact and versatile

OMAX also featured its compact, economical ProtoMAX cutting system at FABTECH 2025. For prototyping and low-volume production, ProtoMAX provides a sleek 12" x 12" (304 mm x 304 mm) cutting envelope for materials up to 1" (25 mm) thick and comes with everything necessary to start cutting anywhere in any place.

"All it requires is single-phase power and access to water and access to a drain, and you can be cutting parts," said Ulmer. "It has a five-horsepower pump built into it. It has garnet delivery system built into it. With the cutting bed of one foot by one foot, you can cut parts up to five thousandths accuracy. You have about one inch of Z travel.

"The really beautiful thing about it (the ProtoMax) is that it cuts any material up to one inch thick that you can put on the table. We make it right here in America, and they're ready to ship right now.