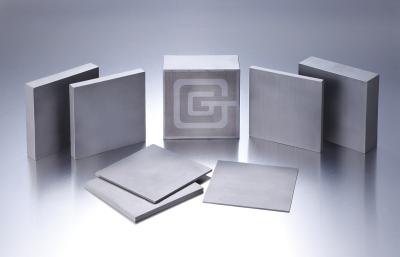

General Carbide has expanded its operations to produce more than 40 standard and custom sizes of WEDM blocks for a range of stamping and fabricating applications. To help ensure that blocks are of the highest metallurgical quality and reach customers intact and quickly, the company processes every order in sinter-HIP furnaces, ships the blocks in durable packaging, guarantees turnaround of 3 to 5 business days and tracks shipments door-to-door.

“Providing superior grades and more WEDM options is the result of listening to customers and prospects, making a significant capital investment,” said Mona Pappafava-Ray, General Carbide’s president and CEO. “Our submicron grain size of tungsten carbide particles is ideal for wear resistant grades capable of withstanding moderate impact loads. In contrast, our 4-micron carbide particle grain size and use of tantalum carbide yield a WEDM block that offers the highest resistance to galling.”

Related Glossary Terms

- galling

galling

Condition whereby excessive friction between high spots results in localized welding with subsequent spalling and further roughening of the rubbing surface(s) of one or both of two mating parts.

- tungsten carbide ( WC)

tungsten carbide ( WC)

Intermetallic compound consisting of equal parts, by atomic weight, of tungsten and carbon. Sometimes tungsten carbide is used in reference to the cemented tungsten carbide material with cobalt added and/or with titanium carbide or tantalum carbide added. Thus, the tungsten carbide may be used to refer to pure tungsten carbide as well as co-bonded tungsten carbide, which may or may not contain added titanium carbide and/or tantalum carbide.