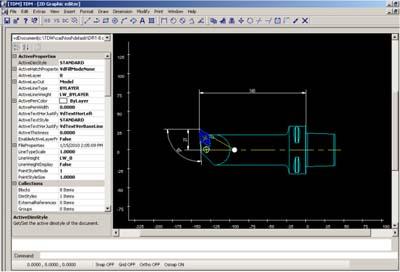

TDM Systems GmbH's new Version 4.4 tool data management software is available. In addition to its many innovations, here are some of the highlights for NC programming and CAD/CAM simulation users: tool assemblies can be put together with various insertion points and on 3 axes, and there's an integrated graphic editor too. The tool crib module can now be installed with 3-tier architecture for faster access by plants at different locations. For Achim Mueller, Technical Director at TDM Systems GmbH, this ability to work with a variety of insertion points is an absolute highlight. What's more, the new TDM release gives the user flexibility in making additions to different items in different directions based on their parameters. "We have modified structures in our Tool Data Management Software in such a way that items can now be inserted at various predefined points." This eliminates calculation by the user himself — a process often beset with errors — and makes work easier, according to the company. In metalcutting production industries, the trend has gone for years more and more in the direction of all-round machining. The aim is to minimize set-up times by using complex multistage tools that require fewer clamping steps. TDM has passed yet another milestone in exactly replicating tool assemblies with a new function: assembly on 3 axes. Now a milling cutter with three inserts can easily be displayed in TDM by positioning items on the "third level," i.e. the Z-axis. "The user only needs to enter the three required angles to see a three-dimensional view of the corresponding coordinate systems according to which the tool is aligned,"says the Technical Director. This function is further enhanced by the TDM Data and Graphics Generator, resulting in true-to-life images for simulation and collision analysis. A further innovation with great benefit for companies with more than one TDM client: The TDM 2D Graphic Editor. This fully integrated module lets the user change technical drawings directly in TDM. Using TDM is now even more comfortable due to the addition of specific functions like XS dimensionsetting, layer conversion, and closure of tool contours: there's no back-andforth between TDM and the CAD application, meaning savings in time and costs.

Contact Details

Related Glossary Terms

- computer-aided design ( CAD)

computer-aided design ( CAD)

Product-design functions performed with the help of computers and special software.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- metalcutting ( material cutting)

metalcutting ( material cutting)

Any machining process used to part metal or other material or give a workpiece a new configuration. Conventionally applies to machining operations in which a cutting tool mechanically removes material in the form of chips; applies to any process in which metal or material is removed to create new shapes. See metalforming.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling cutter

milling cutter

Loosely, any milling tool. Horizontal cutters take the form of plain milling cutters, plain spiral-tooth cutters, helical cutters, side-milling cutters, staggered-tooth side-milling cutters, facemilling cutters, angular cutters, double-angle cutters, convex and concave form-milling cutters, straddle-sprocket cutters, spur-gear cutters, corner-rounding cutters and slitting saws. Vertical cutters use shank-mounted cutting tools, including endmills, T-slot cutters, Woodruff keyseat cutters and dovetail cutters; these may also be used on horizontal mills. See milling.

- numerical control ( NC)

numerical control ( NC)

Any controlled equipment that allows an operator to program its movement by entering a series of coded numbers and symbols. See CNC, computer numerical control; DNC, direct numerical control.