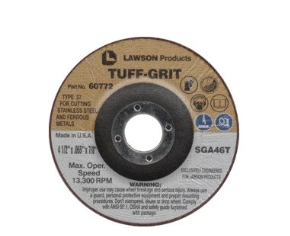

Tuff-Grit Zirconium Grain Premium Grinding Wheels

Tuff-Grit Zirconium Grain Premium Grinding Wheels

The longest-lasting, fastest-cutting abrasive is especially effective for hard-to-grind applications like stainless steel weldments, nickel alloys and ferrous metals.

Grinding Machines & Equipment Grinding Wheels & Abrasives Grinding (Surface, Cylindrical, Tool & Cutter) Machining

Lawson's Tuff-Grit Zirconium Grain Premium Grinding Wheels provide the optimal balance of material removal and wheel life. The longest-lasting, fastest-cutting abrasive is especially effective for hard-to-grind applications like stainless steel weldments, nickel alloys and ferrous metals.

- Premium zirconium aluminum oxide grain is designed to provide ultimate performance over a wide range of applications

- High cutting rates reduce total cost

- Improved operator efficiency – no bouncing or spalling

- Efficient grinding all the way down to a minimum stud for longest life

- Outlast standard aluminum oxide discs 3-to-1

- Type 27 wheel available in 4", 4 1/2", 5" 7" and 9" diameters