SintoGrind HSS from oelheld U.S. was especially developed for profile and flute grinding of steel alloys and in particular for high-speed steel and medical steel.

It is based on synthetic Polyalphaolefins free of chlorine or heavy metal compounds. All additives are synthetic and have excellent high pressure (EP) and superb lubrication properties. Most important the product is physiologically absolutely safe. Oil misting and evaporating tendency is very low and it has an excellent viscosity-temperature relationship.

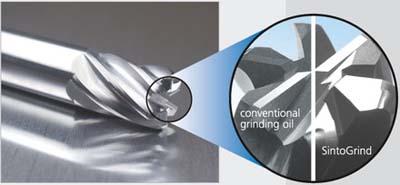

Due to its 100 percent synthetic formula, SintoGrind HSS cools, lubricates and cleans better than any mineral oil based grinding oil and has grinding wheels remain clean and unclogged. SintoGrind HSS has an extremely low evaporation and misting rate and sheds air very quickly and does not foam. Tangential forces and work piece temperatures will be greatly reduced with the use of SintoGrind HSS.

Contact Details

Related Glossary Terms

- alloys

alloys

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- high-speed steels ( HSS)

high-speed steels ( HSS)

Available in two major types: tungsten high-speed steels (designated by letter T having tungsten as the principal alloying element) and molybdenum high-speed steels (designated by letter M having molybdenum as the principal alloying element). The type T high-speed steels containing cobalt have higher wear resistance and greater red (hot) hardness, withstanding cutting temperature up to 1,100º F (590º C). The type T steels are used to fabricate metalcutting tools (milling cutters, drills, reamers and taps), woodworking tools, various types of punches and dies, ball and roller bearings. The type M steels are used for cutting tools and various types of dies.