Robot-based Drilling, Grinding, Filing, Cutting and Deburring

Robot-based Drilling, Grinding, Filing, Cutting and Deburring

In cases where the cutting tool must be moved towards the workpiece, insufficient or not many practical solutions are readily available. This gap is being closed by the SUHNER robot machine tool program. One option is to bring the workpiece towards a standard stationary SUHNER machining unit. Today, SUHNER offers the possibility to adapt and guide the tool by the robot.

In cases where the cutting tool must be moved towards the workpiece, insufficient or not many practical solutions are readily available. This gap is being closed by the SUHNER robot machine tool program. One option is to bring the workpiece towards a standard stationary SUHNER machining unit. Today, SUHNER offers the possibility to adapt and guide the tool by the robot.

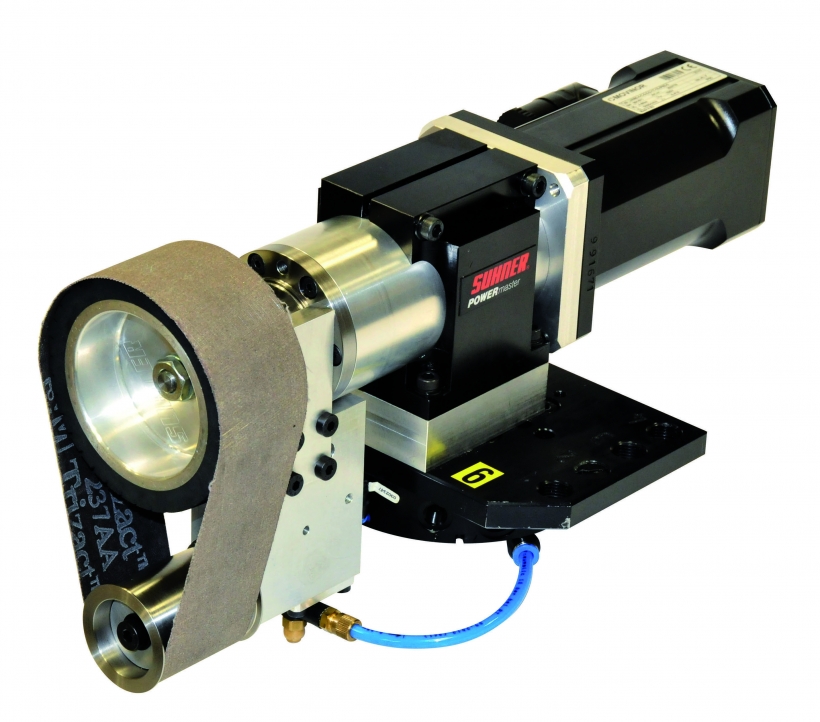

As a specialist in automation processes, machining units, hand held power tools and abrasives, SUHNER expanded its product range with special tools, that can be mounted directly to the robot arm. Thanks to a quick change tool adaptation system, a number of powerful machine tools can be connected directly to the robot, ready for continuous industrial use.

The application range is enormous. From vehicle manufacturing to deburring operations, from stainless steel machining to drilling and tapping operations, all areas of manufacturing and all types of operations are covered. Specifically, for surface treatment and conditioning applications, SUHNER Machining can benefit from a long and extensive experience of its popular SUHNER Abrasive product program. Products for brushing, polishing, filing, belt sanding or tool spindles are easily intergrated in this new program, designed and tested for continuous operation.

Active Contact Flanges

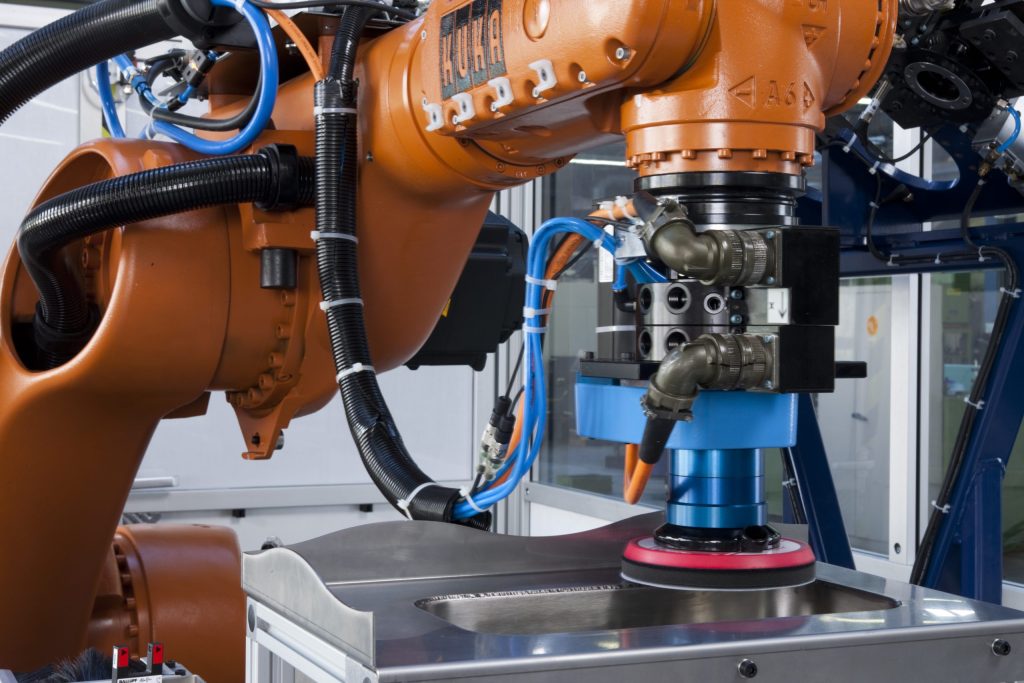

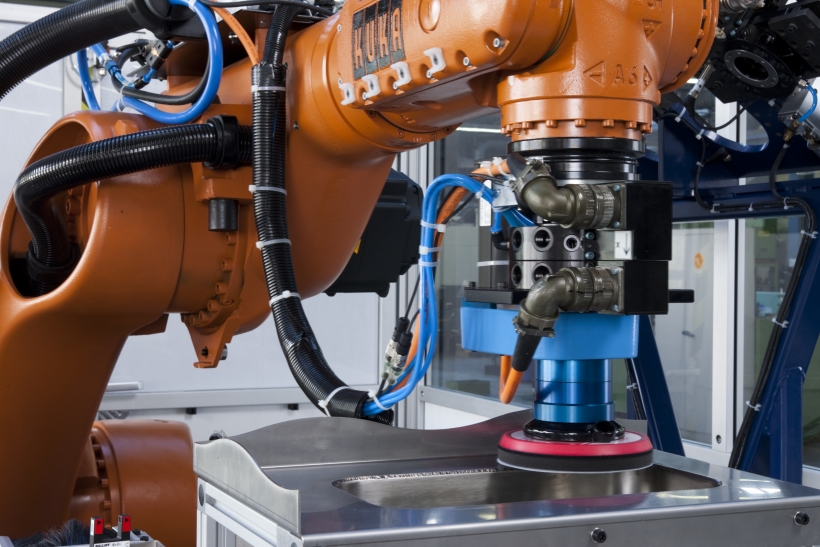

SUHNER says it has perfected the two most important factors: a combination between robot feed movement and the actual toolpath and process. Specifically for round and irregular shaped pieces and surfaces, a human sense for touch, that helps to meter and monitor required forces in an adaptive way. Anyone can imagine the grinding and polishing of a special shaped part in a car body shop or in a woodworking shop. At all times, when a non-linear operation or movement takes place, the active flange will become necessary.

The touch forces of the active flange are programmable, the surface tracking is interactive and best of all, the system can be integrated on all robots. Operations that were not suitable for automation in the past, can now be automated.

Points:

1. Process forces are programmable

2. Tolerances (shapes) will be balanced

3. Programming time and effort (at the robot) for complex parts will be reduced

4. Performance and process assurance compared to known systems such as load cells, can be drastically increased.

Quick-Change Systems

Standardized connections at the robot arm and the tool are used to automate the quick change system. Connections are made quickly and reliably between air and hydraulic mediums, electrical or sensor technology.

One of the key requirements for quick connecting components is to apply proven technology with a high degree of interchange reliabilty. Selected components meet this requirement.

A worldwide presence in sales and distribution of SUHNER products together with another international manufacturer for connecting elements is an ideal partnership for the SUHNER Power-Pack robot machine tool program. Its compatibility with all robot manufacturers makes it even more versatil for demanding high-performance applications.

Change of the Abrasives

Abrasives typically have a short life cycle. A patended, simple quick change of abrasives system (dispose and reload) was added to the program to simplify the change of abrasives.

This quick change for abrasive system from SUHNER, for example, allows the use of seven different abrasives in sequence to achieve a desired surface finish.

An automated abrasive change increases the flexibility and eliminates unproductive production hours.

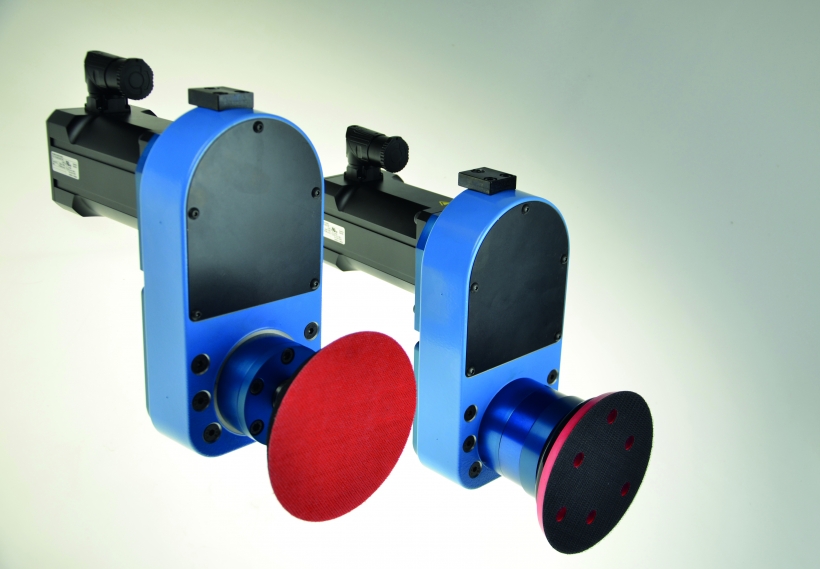

Angle grinders in standard execution and as excenter grinder.

Servomotor-driven angle grinders

Today, most robot-guided grinding and polishing machine tools are operated by air. Often, considering a 24 hours operating environment, these machines reach their limits. Frequent service interruptions plus extremely high air consumption add to energy cost that also will affect profitabilty. In addition, air-driven tools drop in speed when under load which can contribute to an adverse effect to the surface finish. Depending on surface quality requirements, the rotation of the grinding or polishing tool often requires clock and counter-clock rotation, which an air driven tool can't accomplish. All of these critical requirements can be met with servo-driven tools from SUHNER either in standard or excenter design version. Lightweight and powerful servomotors are used to obtain high speeds up to 12,000 rpm with timing belt drive components made for continuous operation. Adapter flanges facilitate exchange and attachment to all robot flange designs. Delivery includes a servo control module. All grinding tools are made with an M 14 spindle to enable the use of commercially available grinding discs.

Just like SUHNER machining units, robots can easily be adapted to perform different tasks in an ever changing production environment. In the plumbing fixture industry, a large iron casting is being machined in a production line utilizing a SOMEX machining unit type MAX100 and a FANUC robot type 200iB. Applications even in a test laboratory. At one of the top engineering universities in the USA is conducting tests with a Kuka robot (KR-Fortec) and a SUHNER machining unit (BEX35-ISO). These material tests are made for one of the world's leading aerospace companies. A load cell measures forces (stress) when machining different materials commonly used in the aerospace industry. Material can range from composites to titanium. The machining data is transferred wirelessly from the sensor inside the toolholder to the laptop for storage and analysis. Testing results are used to make improvements in material thickness or selection, as well as understanding and predicting load limits.

SUHNER Components for Robot-Guided Operations – Integrable for all Robots

Tools: Air motor milling spindles, files, belt sanders and machining units. Diverse range of tools for deburring, polishing, cutting.

Robust machining units for demanding applications with or without automated tool change for complete factory automation.

Abrasives: Development and training for different materials and applications.

Special equipment: Special contact flange with integrated force compensation

Abrasives change station: Fully automated change of abrasives made for industrial continuous operation.

Special machine tool builder: Integration of robots and robot tools. Decades of experience in metal and chip making industry, machine tool building and metal surface conditioning.

Testing lab: Possibility of process testing in company's lab upon customer request.