Wintriss Controls Group has announced a new ProCamPAC PRO Programmable Limit Switch (PLS) for its flagship SmartPAC PRO Press Automation Controller. Building on the proven functionality of the ProCamPAC PLS, the new “PRO” PLS features five additional cam timing options that provide unprecedented flexibility and functionality.

“Until now, Programmable Limit Switches have remained largely unchanged, so we are very pleased to offer our customers powerful new features in our ProCamPAC PRO, the industry’s most advanced PLS,” said Jim Finnerty, Wintriss Controls Group Product Manager.

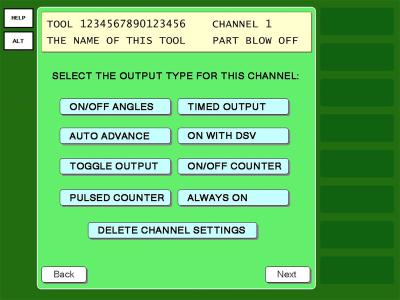

A new Toggle Cam Output performs an asymmetrical toggle function, turning an output off or on for different stroke amounts. The output can be used to operate diverter gates and to control complex gagging operations. The new On/Off Counter Cam Output precisely controls functions that need to operate at a preset interval instead of on every machine cycle. Operating similarly, a new Pulsed Counter Cam Output is programmed with an “on angle” and a dwell time instead of an on-off output.

Useful when running configurable tooling, a new Channel Always On Cam Output will simply turn on and stay on until a new tool is loaded. ProCamPAC PRO PLS also features a unique Triggered Cam Output which actuates a precision one-time cam timing signal based on a preset trigger such as an external input from ancillary equipment, an extended period of machine idle time, or a job change. This output type is ideal for diverting parts during a warm-up period, QC checks or when bad parts are determined by an outside measuring system.

Contact Details

Related Glossary Terms

- computer-aided manufacturing ( CAM)

computer-aided manufacturing ( CAM)

Use of computers to control machining and manufacturing processes.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.