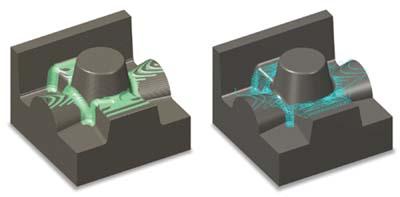

OptiRest is the latest 3D high-speed toolpath from Mastercam. It performs rest rough milling operations to remove stock left from roughing passes with large cutters. This powerful new toolpath compares the in-process stock model to the intended shape to create an optimized dynamic milling cleanup pass. The result is precise, efficient motion that is easier on your tooling and your machine.

The toolpath supports cutters capable of machining very large depths of cut. It uses an aggressive, fast, intelligent roughing algorithm based on Mastercam's 2D high speed dynamic milling motion. A single toolpath can cut material in two directions: on step downs (-Z) and step ups (+Z). This highly efficient bi-directional cutting strategy removes the maximum amount of material with the minimum of step downs, significantly reducing cycle times.

"The beauty of OptiRest is that you don't need any special tooling to use it. It simply uses the tools you have now, but in a much more efficient way," says Gary Hargreaves, VP, Business Development.

Contact Details

Related Glossary Terms

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- toolpath( cutter path)

toolpath( cutter path)

2-D or 3-D path generated by program code or a CAM system and followed by tool when machining a part.