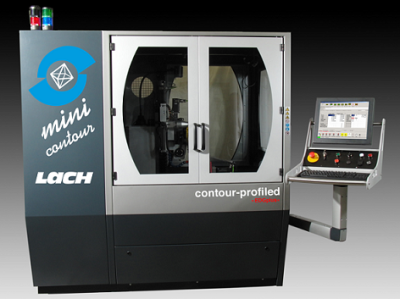

Lach Diamond Inc. developed «mini-contour» machines, a special sharpening machine that can produce high-precision concave and convex profiles from 2 to 4 µm and is suitable for re-sharpening the company's »contour-profiled« grinding wheels.

In addition, «mini-contour» machines are available for service or purchase, both for manufacturers and end customers. The «mini contour» sharpening machine enables the EDG procedure.

Contact Details

Related Glossary Terms

- electrical-discharge grinding ( EDG)

electrical-discharge grinding ( EDG)

Process similar to conventional electrical-discharge machining except a grinding-wheel type of electrode is used. See EDM, electrical-discharge machining.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.