A single-station CNC microfinishing system processes a family of 68 aerospace control surface actuation shafts to better than 0.1 Ra, while creating a functional surface for the component. Other tribological surface parameters are used for this post-grinding application on HVOC (tungsten carbide) coated steel shafts.

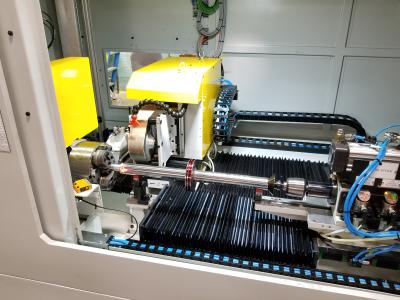

Besides meeting surface finish requirements, the IMPCO Microteq Microfinsher reduced the cycle time to process the shafts from minutes to seconds in process time, with a consistency from feature to feature and part to part. The IMPCO Microteq CNC machine uses the company’s exclusive designed and built microfinishing attachment loaded with abrasive film.

Previously, each of the shafts in the family of parts had to be set up manually, then processed by hand resulting in inconsistent part surface quality, across the journal, from feature to feature and part to part.

The flexible IMPCO machine is designed to microfinish different diameters up to 75mm on any precision load-bearing shaft to 1,000 mm in length. Such shafts are used in pumps, compressors, aerospace control surfaces, and transmissions. Loading and unloading may be manual, automatic, or robotic.

In operation, the shaft is loaded horizontally between centers and rotated with a head stock as the microfinishing attachment automatically approaches the part. The microfinishing head loaded with abrasive film travels on a horizontal slide to contact the shaft and the process begins. After predetermined cycle time, the microfinishing head and is returned to its starting point or can move laterally to microfinish an adjacent diameter. The head stock with independent geared drive rotates the part at a predetermined speed, between 100 and 1,000 rpm.

Microfinishing is the process that removes the microscopic amorphous surface material left from the grinding of a dimensionally finished part, such as a crankshaft, camshaft, or pump shaft, to permit a highly precise fit to a mating part. IMPCO microfinishing is used to generate the final functional surface texture required for friction reduction, higher performance and greater reliability of the precision shafts. Microfinishing tolerances are unattainable with grinding, said Mark Hendel, IMPCO global sales director.

Contact Details

Related Glossary Terms

- abrasive

abrasive

Substance used for grinding, honing, lapping, superfinishing and polishing. Examples include garnet, emery, corundum, silicon carbide, cubic boron nitride and diamond in various grit sizes.

- amorphous

amorphous

Not having a crystal structure; noncrystalline.

- centers

centers

Cone-shaped pins that support a workpiece by one or two ends during machining. The centers fit into holes drilled in the workpiece ends. Centers that turn with the workpiece are called “live” centers; those that do not are called “dead” centers.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- family of parts

family of parts

Parts grouped by shape and size for efficient manufacturing.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- surface texture

surface texture

Repetitive or random deviations from the nominal surface, which form 3-D topography of the surface. See flows; lay; roughness; waviness.