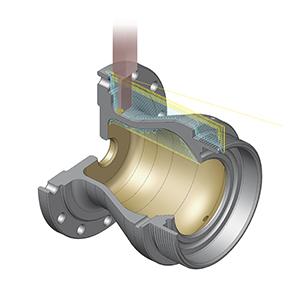

From accepting and programming any CAD file to Dynamic roughing and precision finishing, Mastercam 2017 Lathe gives you a variety of techniques to turn all of your parts exactly as you need them. Mastercam 2017 Lathe features a new Chip Break option, TNRC Control and Stock Model Enhancements.

The Align Solid Body function simplifies the process of aligning solid models for turning. You can define the center of the rotation for the part and select the appropriate geometry. Mastercam will then rotate to an isometric view where you can use the dynamic gnomon to adjust the origin.

A new option and dialog box has been added to the Lathe Rough and Lathe Contour Rough toolpaths to establish when chip breaks occur. This is valuable when working with stringy materials such as aluminum or plastic, and allows you to set length and time conditions, retract, and dwell options.

The Tool Angle dialog box contains new options which were previously only available for Mill-Turn operations. These options tell Mastercam which quadrant you used to touch off your tool. If you are creating a toolpath and the tool’s control point is not where you want it, you can use these options to swap it.

Also available in the Mastercam 2017 Lathe is:

- Simplified process for selecting the tool plane, origin, and display mode in the Lathe operations.

- The new Axis Combination / Spindle Origin dialog box filters available tool planes, displaying only those planes with the correct orientation for the selected axis combination.

- Lathe Stock Model operations now allow you to manipulate the Lathe stock boundary using Mill operations.

Contact Details

Related Glossary Terms

- computer-aided design ( CAD)

computer-aided design ( CAD)

Product-design functions performed with the help of computers and special software.

- lathe

lathe

Turning machine capable of sawing, milling, grinding, gear-cutting, drilling, reaming, boring, threading, facing, chamfering, grooving, knurling, spinning, parting, necking, taper-cutting, and cam- and eccentric-cutting, as well as step- and straight-turning. Comes in a variety of forms, ranging from manual to semiautomatic to fully automatic, with major types being engine lathes, turning and contouring lathes, turret lathes and numerical-control lathes. The engine lathe consists of a headstock and spindle, tailstock, bed, carriage (complete with apron) and cross slides. Features include gear- (speed) and feed-selector levers, toolpost, compound rest, lead screw and reversing lead screw, threading dial and rapid-traverse lever. Special lathe types include through-the-spindle, camshaft and crankshaft, brake drum and rotor, spinning and gun-barrel machines. Toolroom and bench lathes are used for precision work; the former for tool-and-die work and similar tasks, the latter for small workpieces (instruments, watches), normally without a power feed. Models are typically designated according to their “swing,” or the largest-diameter workpiece that can be rotated; bed length, or the distance between centers; and horsepower generated. See turning machine.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

- toolpath( cutter path)

toolpath( cutter path)

2-D or 3-D path generated by program code or a CAM system and followed by tool when machining a part.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.