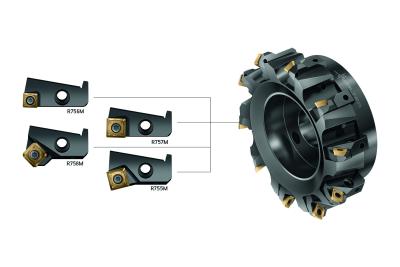

Walter has expanded its milling program with additions that allow the universal, square system inserts of its versatile M4000 milling line to be used in its F2010 program, which is a milling family that utilizes a replaceable and adjustable cartridge.

Cartridges are now available to convert the standard F2010 mill bodies into the following: the M4002, which is a 15° lead high-feed mill; the M4003, a 45° lead mill; and the M4132, a 90° shoulder mill, which is available in two different insert sizes. By launching these four new cartridges for the F2010 face and shoulder milling cutter line, Walter has significantly expanded the application scope of the M4000 range, bringing the M4000’s benefits to the machining of medium and large components.

These benefits include soft cutting action plus positive geometry, resulting in high metal-removal rates and optimal efficiency. Previously the M4000 was available only in diameters up to 6 in. (160 mm), but these new cartridge-based milling cutters come in a diameter range of 3.15-12.4 In. (80–315 mm) and can be used to machine medium and large components as well as small ones, efficiently and economically.

The design, which consists of a basic body plus four adjustable or interchangeable cartridge-types makes the F2010 a good choice for those who want to carry out shoulder milling, face milling, or high-feed milling operations. The adjustable nature of the cartridges enables the runout to be fine-tuned to produce superior surface quality. Add to this, the inherent advantages of the M4000 system—and the exceptional versatility of M4000, which is suitable for steel and cast-iron workpieces, stainless steels, materials with difficult cutting properties, aluminium and other non-ferrous metals. These benefits make the system relevant to users working in a wide range of fields, such as general mechanical engineering, the aviation and aerospace sector, and the automotive industry.

Contact Details

Related Glossary Terms

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling cutter

milling cutter

Loosely, any milling tool. Horizontal cutters take the form of plain milling cutters, plain spiral-tooth cutters, helical cutters, side-milling cutters, staggered-tooth side-milling cutters, facemilling cutters, angular cutters, double-angle cutters, convex and concave form-milling cutters, straddle-sprocket cutters, spur-gear cutters, corner-rounding cutters and slitting saws. Vertical cutters use shank-mounted cutting tools, including endmills, T-slot cutters, Woodruff keyseat cutters and dovetail cutters; these may also be used on horizontal mills. See milling.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

- stainless steels

stainless steels

Stainless steels possess high strength, heat resistance, excellent workability and erosion resistance. Four general classes have been developed to cover a range of mechanical and physical properties for particular applications. The four classes are: the austenitic types of the chromium-nickel-manganese 200 series and the chromium-nickel 300 series; the martensitic types of the chromium, hardenable 400 series; the chromium, nonhardenable 400-series ferritic types; and the precipitation-hardening type of chromium-nickel alloys with additional elements that are hardenable by solution treating and aging.