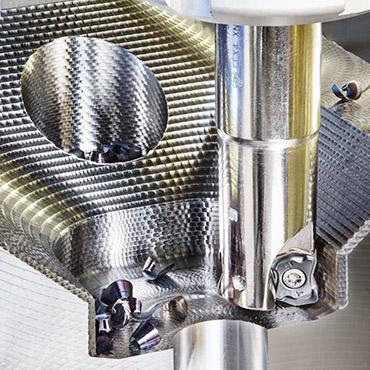

LOGIQ-4-FEED, a family of indexable cutters for rough machining and high feed milling. These cutters feature narrow "bone-shaped" double-sided inserts with four cutting edges.

LOGIQ-4-FEED was originally designed for roughing operations, particularly when machining deep cavities mainly in the die and mold and aerospace industries. Later, LOGIQ-4-FEED expanded its application range to other industrial sectors.

Each "bone- shaped" insert has a minor cutting edge for improved cutting action in ramp-down milling.

These inserts have 4 types of cutting geometries for machining different materials under diverse cutting conditions:

T - Steel, ferritic and martensitic stainless steel, cast iron and hardened steel

HP - Austenitic stainless steel and high temperature alloys

RM-T - Interrupted cut for machining near straight wall shoulders of steel, ferritic and martensitic stainless steel, cast iron, and hardened steel

RM-HP - Interrupted cut for machining near straight wall shoulders of austenitic stainless steel and high temperature alloys

Features:

- Available in two subfamilies: for mounting inserts of 04 mm and 08 mm sizes

- 17° cutting edge angle.

- Progressive cutting geometry reduces cutting forces for smooth cutting.

- Ramping down capability.

- Protective coating on cutter body for uninterrupted chip flow and protection against corrosion and wear.

- Internal coolant holes directed to each cutting edge.

Operation capability:

Diameter range

- Metric: 12-52 mm

- Imperial: .5"-2.0”

Insert size: 04

Insert Carbide Grades

IC808, IC830, IC840, IC882, IC5820

Contact Details

Related Glossary Terms

- alloys

alloys

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- interrupted cut

interrupted cut

Cutting tool repeatedly enters and exits the work. Subjects tool to shock loading, making tool toughness, impact strength and flexibility vital. Closely associated with milling operations. See shock loading.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.