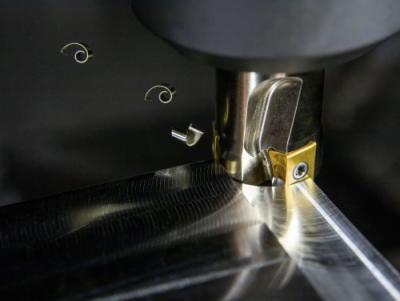

A new assortment of Pramet LNEX 12 negative tangential inserts, with four cutting edges, provides a highly productive solution for a wide range of applications. The LNEX 12 is a robust insert designed for shoulder milling with a maximum depth of cut up to 10 mm. It features a positive rake angle and narrow T-land to provide a smooth cutting action with lower demands on spindle torque.

The peripherally ground insert offers improved wall accuracy and straightness and creates a true 90° corner. The LNEX12 also featuring a patented U-groove segment on all four cutting edges which provide a good surface finish and expand its application range to low-power machines and small depths of cut. In addition, the two-sided design supports performance by making ramping possible.

The insert comes in two different geometries, F- for machining of various workpiece materials in light and medium applications. While M- is suited for medium to semi-roughing in steels and cast irons.

Alongside the new insert is a line of perfectly matched cutters. The Pramet SLN12X series is available in Cylindrical, Weldon and Shell styles, with all featuring internal coolant systems for improved surface quality.

Its improved body strength and thick core offers enhanced rigidity, giving a reliable cutting process with low vibrations and long tool life for both the insert and cutter. Easily accessible large clamping screws provide simple indexing and handling of inserts.

The combination of the Pramet LNEX 12 inserts and the SLN12X cutters give operators a smooth cut with a clean finish, reducing the need for additional operations, such as deburring.

Contact Details

Related Glossary Terms

- cast irons

cast irons

Cast ferrous alloys containing carbon in excess of solubility in austenite that exists in the alloy at the eutectic temperature. Cast irons include gray cast iron, white cast iron, malleable cast iron and ductile, or nodular, cast iron. The word “cast” is often left out.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- depth of cut

depth of cut

Distance between the bottom of the cut and the uncut surface of the workpiece, measured in a direction at right angles to the machined surface of the workpiece.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- rake

rake

Angle of inclination between the face of the cutting tool and the workpiece. If the face of the tool lies in a plane through the axis of the workpiece, the tool is said to have a neutral, or zero, rake. If the inclination of the tool face makes the cutting edge more acute than when the rake angle is zero, the rake is positive. If the inclination of the tool face makes the cutting edge less acute or more blunt than when the rake angle is zero, the rake is negative.