Kennametal has introduced its latest ceramic turning grade, KYHK15B™, designed to deliver increased productivity and lower cost per edge in hard turning operations. The new grade provides greater depth of cut capabilities than PcBN inserts when machining hardened steel, high-temperature alloys, and cast iron, as well as maximum tool life and wear resistance for the most demanding turning applications.

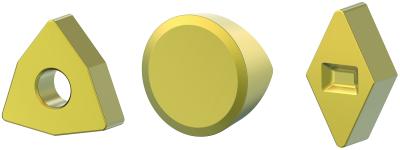

A broad range of styles, sizes, and edge preparations are available. These include the most popular styles of double-sided roughing and finishing inserts for predictable, cost-effective machining.

"KYHK15B provides excellent edge stability, high chipping resistance, and a PVD gold coating makes wear progression identification very easy. From smooth and varying depths of cut to heavy depths of cut, KYHK15B can be an economic alternative to PcBN inserts," says Robert Keilmann, Product Manager, Kennametal.

Depending on the surface requirement and the type of cut, the ceramic grade KYHK15B can be an economic alternative to PcBN inserts when machining hard materials >48 HRC.

KYHK15B builds on an existing line of high-performance ceramic turning grades, providing manufacturers a productive solution for hard turning applications even in varying or heavy depths of cut.

Contact Details

Related Glossary Terms

- alloys

alloys

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

- depth of cut

depth of cut

Distance between the bottom of the cut and the uncut surface of the workpiece, measured in a direction at right angles to the machined surface of the workpiece.

- hard turning

hard turning

Single-point cutting of a workpiece that has a hardness value higher than 45 HRC.

- physical vapor deposition ( PVD)

physical vapor deposition ( PVD)

Tool-coating process performed at low temperature (500° C), compared to chemical vapor deposition (1,000° C). Employs electric field to generate necessary heat for depositing coating on a tool’s surface. See CVD, chemical vapor deposition.

- polycrystalline cubic boron nitride ( PCBN)

polycrystalline cubic boron nitride ( PCBN)

Cutting tool material consisting of polycrystalline cubic boron nitride with a metallic or ceramic binder. PCBN is available either as a tip brazed to a carbide insert carrier or as a solid insert. Primarily used for cutting hardened ferrous alloys.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

- wear resistance

wear resistance

Ability of the tool to withstand stresses that cause it to wear during cutting; an attribute linked to alloy composition, base material, thermal conditions, type of tooling and operation and other variables.