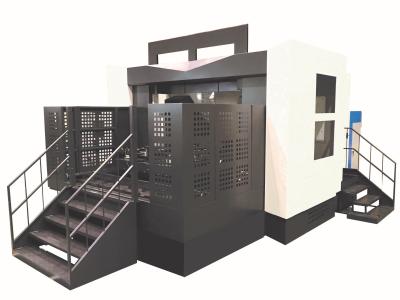

New from Niigata Machine Techno USA, Inc., the HN80E-5X 5-Axis Horizontal Machining Center is the latest and largest addition to the builder’s heavy-duty HN-5X Series. The HN80E-5X features an impressive 49.2” of travel in the X-axis, 48.4” in Y and 47.2” in Z, and allows a maximum workpiece diameter of 49.2”, height of 39.4” and weight of 3,300 lb. Incorporating the solid cast iron X and Z base of Niigata’s HN100D-II Heavy Duty Boxway Horizontal Machining Center, the HN80E-5X provides maximum rigidity, stability and accuracy.

The simultaneous 5-axis machining of the HN80E-5X results in improved cycle times and machined surfaces of complicated and 3D curved components. A quick and easy 5-axis compensation function ensures high accuracy over extended periods. Five-face machining means a reduced number of setups and simplified fixtures for a substantially reduced changeover time. For additional efficiency, the tool magazine is driven by a servo motor for fast and reliable indexing.

As with all HN-5X machines, the guide ways of the HN80E-5X consist of a combination of hardened and ground hand-scraped turcite for stability and vibration damping characteristics, as well as a long life. The cross section of the rectangular guide ways is thick and wide for maximum machine rigidity. Niigata’s unique bifurcated bell-shaped column further contributes to rigidity and metal cutting efficiency.

Both ends of Niigata’s exclusively designed heavy duty 5-axis trunnion table are supported by the High Load Type Roller BRG and a Double-Lead Worm Gear System for low frequency machining. For consistent long-life dynamic machine accuracy, the HN80E-5X is equipped with an optical scale feedback system (on X, Y, Z axes) and an inductive scale feedback system (on A, B axes) as standard.

A high torque, heavy duty spindle complements the rigid machine frame. The spindle head stock consists of mono-cast (single piece) castings for more powerful milling and greater accuracy than bolt-together type spindle heads.

The HN80E-5X comes equipped with the FANUC 30iM controller. A variety of 5-axis machining support software is available.

The HN80E-5X is ideal for machining in a range of industries demanding highly rigid, heavy duty and accurate performance, including aircraft, automobile, power generator, die & mold and semiconductor.

As the horizontal machining center specialist, Niigata world-class solutions feature high-speed, accurate and productive performance. The wide range of models includes heavy-duty boxway, roller guide and hybrid (boxway and roller guide) machines, with work envelopes reaching 1600mm. For versatile machining, Niigata also offers a line of facing centers and bar machines.

Contact Details

Related Glossary Terms

- centers

centers

Cone-shaped pins that support a workpiece by one or two ends during machining. The centers fit into holes drilled in the workpiece ends. Centers that turn with the workpiece are called “live” centers; those that do not are called “dead” centers.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- machining center

machining center

CNC machine tool capable of drilling, reaming, tapping, milling and boring. Normally comes with an automatic toolchanger. See automatic toolchanger.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.