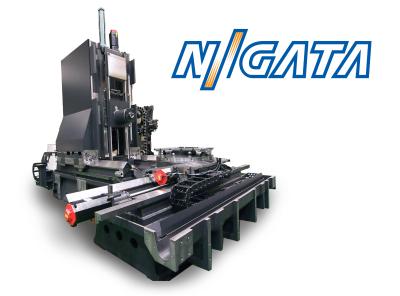

Niigata Machine Techno USA, Inc.’s HN800-V HMC offers the performance of a high-speed jig borer with minimal investment increase over traditional HMC’s.

The HN800-V is uniquely built with the rigidity and accuracy necessary to perform ultra-precise contour machining and boring of components with critical tolerances. The world’s first machining center to feature hardened and ground inverted V-shaped slideways, the HN800-V achieves volumetric accuracy of .00005” per foot. The V-shaped slideway system converts the weight of the column unit into restraining force on the sliding unit. This restraining force provides superior stability, long-term axis straightness of motion that virtually eliminates pitch & yaw motion. The combination of hand-scraped slideways and hardening-processed slide guides maximize the machine durability.

The V-shaped slideways, consisting of anti-abrasion material, also contribute to the high-speed performance of the machine. Achieving rapid traverse of 50m/min (1968 ipm for productivity.

For extreme stability, this V shaped Slideway machine features a solid meehanite cast iron frame with extensive ribbing. Further contributing to precision performance is a powerful and rugged geared high torque spindle. It is constructed with seven sets of wide-spaced, super precision angular contact and roller bearings. The spindle head stock utilizes a mono-cast (single piece) casting to achieve heavy and powerful milling capability and greater stability than bolt-together type spindle heads.

The HN800-V’s pallet clamping system utilizes a stable clamper plate to ensure optimum down force and increased clamping forces of the pallet during extreme cutting conditions. Jets of air discharge from the tapered cones when the pallet is changed to ensure proper clamping and to cleanse seating surfaces.

The HN800-V offers 1530mm (60.2") X-axis travels, 1230mm (48.4") Y-axis travels, 1020mm (40.2") Z-axis travels, and a B-axis rotary angle of 360,000 positions. Maximum workpiece swing diameter is 1750mm (68.9"), the largest work envelope in its class. Maximum workpiece height is 1400mm (55.1”).

As the horizontal machining center specialist, Niigata’s world-class high throughput solutions feature high accuracy, high rigidity, and high-speed. The wide range of models offer heavy-duty V-shaped slideways, boxway, roller guide and hybrid (boxway and roller guide) machines, work envelopes to 1600mm. For versatile machining, Niigata also offers a 5-Axis Series, a FC Series with U-axis and quill for single set-up combined turning operations with machining center operations, and a Bar/Quill Series. Many optional features are available, including Niigata pallet magazine systems.

Contact Details

Related Glossary Terms

- boring

boring

Enlarging a hole that already has been drilled or cored. Generally, it is an operation of truing the previously drilled hole with a single-point, lathe-type tool. Boring is essentially internal turning, in that usually a single-point cutting tool forms the internal shape. Some tools are available with two cutting edges to balance cutting forces.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- inches per minute ( ipm)

inches per minute ( ipm)

Value that refers to how far the workpiece or cutter advances linearly in 1 minute, defined as: ipm = ipt 5 number of effective teeth 5 rpm. Also known as the table feed or machine feed.

- jig

jig

Tooling usually considered to be a stationary apparatus. A jig assists in the assembly or manufacture of a part or device. It holds the workpiece while guiding the cutting tool with a bushing. A jig used in subassembly or final assembly might provide assembly aids such as alignments and adjustments. See fixture.

- machining center

machining center

CNC machine tool capable of drilling, reaming, tapping, milling and boring. Normally comes with an automatic toolchanger. See automatic toolchanger.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- pitch

pitch

1. On a saw blade, the number of teeth per inch. 2. In threading, the number of threads per inch.

- rapid traverse

rapid traverse

Movement on a CNC mill or lathe that is from point to point at full speed but, usually, without linear interpolation.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

- work envelope

work envelope

Cube, sphere, cylinder or other physical space within which the cutting tool is capable of reaching.