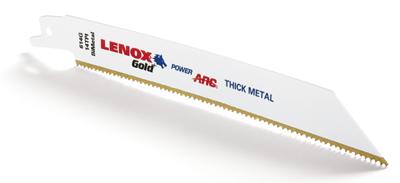

Continuing to redefine the reciprocating saw blade category, LENOX has introduced a curved reciprocating saw blade. The curved design, T2 Technology and precision applied titanium coating come together in the new LENOX Gold Power Arc Curved Blades to deliver up to two times the cutting life of standard LENOX straight blades. The LENOX Gold Power Arc Curved Blades are designed for wood and metal cutting, as well as demolition and extreme heavy metal cutting applications.

"LENOX Gold Power Arc Curved Blades are designed for the heavy recip user who understands the value of investing in a premium product that will deliver superior cutting performance," said Matt Savarino, Brand Manager for LENOX. "These blades last up to twice as long as standard straight LENOX recip blades, allowing trade professionals to be more productive on the job and to achieve more efficient results."

The Power Arc's curved design optimizes the cutting angle, allowing the blade to cut aggressively and more efficiently versus a straight blade. In a series of laboratory tests using typical reciprocating saw parameters, Power Arc blades outperformed competitive brands when cutting materials such as nail-embedded wood, black pipe, uni-strut and other common construction materials.

An aggressive blade design and proprietary technologies, such as T2 Technology and a titanium coating, enable LENOX Gold Power Arc Curved Blades to achieve extended life. T2 Technology and the precision applied titanium coating help to disperse heat, a common reason reciprocating saw blades wear out quickly, allowing the blade to last longer.

Contact Details

Related Glossary Terms

- sawing machine ( saw)

sawing machine ( saw)

Machine designed to use a serrated-tooth blade to cut metal or other material. Comes in a wide variety of styles but takes one of four basic forms: hacksaw (a simple, rugged machine that uses a reciprocating motion to part metal or other material); cold or circular saw (powers a circular blade that cuts structural materials); bandsaw (runs an endless band; the two basic types are cutoff and contour band machines, which cut intricate contours and shapes); and abrasive cutoff saw (similar in appearance to the cold saw, but uses an abrasive disc that rotates at high speeds rather than a blade with serrated teeth).