Six steps to custom design and build workholding solutions

Six steps to custom design and build workholding solutions

Jergens Custom Design and Build workholding solutions are engineered around part configurations using standard products and a six-step process to reduce cost and lead time for customers.

Jergens Custom Design and Build workholding solutions are engineered around part configurations using standard products and a six-step process to reduce cost and lead time for customers.

The advancements in the program are proven to guide customer decisions regarding the use of a dedicated solution versus standard off-the-shelf products, pinpointing Return on Investment (ROI) and productivity calculations.

The six steps to Jergens' Custom Design and Build program begin with the decision, or need, for a custom solution and proceed to concept, cost and timing, customer approval, initiation of manufacturing, and ultimately delivery. The process presents clear steps and milestones for both parties to reduce development time.

"There are a number of key objectives we focus on when recommending these solutions to a customer, they include achieving the greatest machining access, maximized number of fixtured parts, and minimal changeover for the shortest cycle times possible," said Omar Andino, Jergens National Sales Manager for the Workholding Solutions Group. "Our six steps simplify and clarify the process, providing a streamline collaboration between our folks and customer stakeholders," Andino continued.

Adding quick-change to production boosts customer performance by minimizing changeover and setup time. Additionally, building a solution tailored to the exact needs of the component helps customers increase machining access, meet tight tolerances, shorten cycle times, achieve the lowest cost per part, and free up additional capacity. All of which supports high productivity as well as predictable and fast ROI.

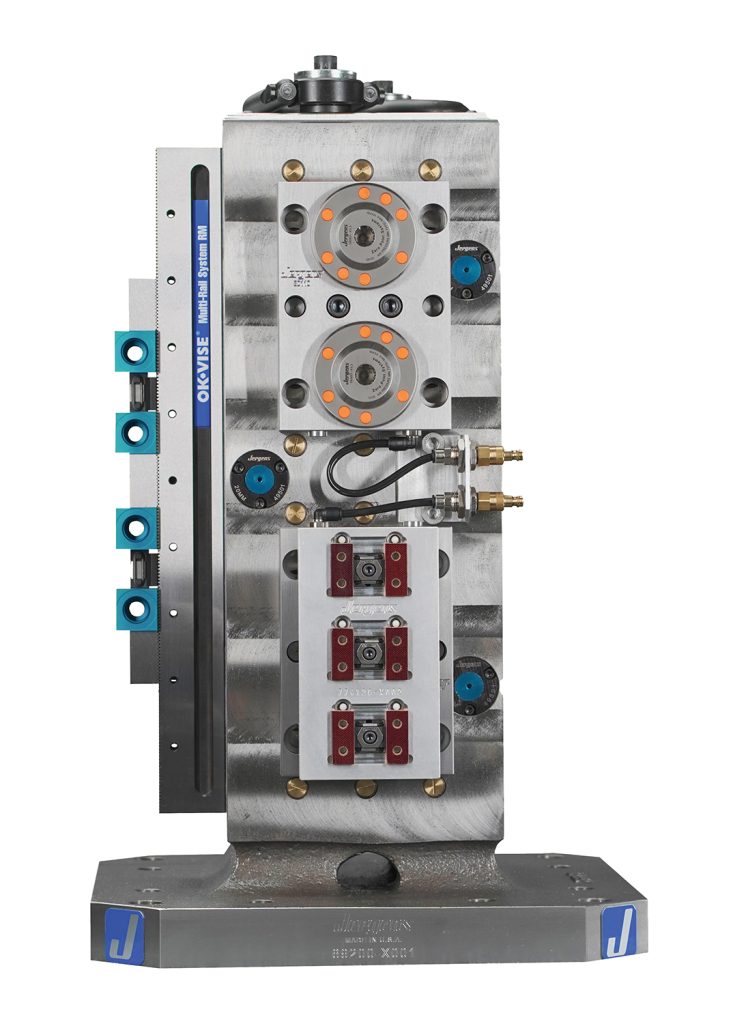

Among the many Jergens products used are Ball-Lock mounting systems, QLS tooling columns, OK-Vise low-profile edge clamps, and Zero Point System (ZPS). To produce the solution, Jergens relies on its decades of experience in engineering and manufacturing quick-change workholding systems.

Successes with these unique solutions can be quite substantial. One such example with an automotive component manufacturer involved changing the machine tool from a vertical machining center with a 4th axis rotary table to a horizontal machining center using a tombstone fixture. A second change was to replace manual clamping with a hydraulic system. Finally, an all-new fixture was created to make full use of the alternate machine and workholding. The results were a reduction of setup from 4 hours (on the high end) to just 25 seconds, in total taking 61% out of the overall cost to produce each part.