In 1978, LACH DIAMANT discovered the use of spark erosion as a means of forming polycrystalline cutting materials and allowing for the production of rotating PCD tools, e. g. step drills and profile tools. Since then, PCD diamond tools have established themselves in metal, wood and plastic industries all over the world.

Since 1973, when polycrystalline diamond cutting materials were first available, LACH DIAMOND has develops and manufactures cutting tools, especially for milling and turning cutters. The discovery of spark erosion made it possible for industry pioneer LACH DIAMOND to complete the company’s product range with rotating PCD tools, milling cutters, profile tools, saws and wear tools.

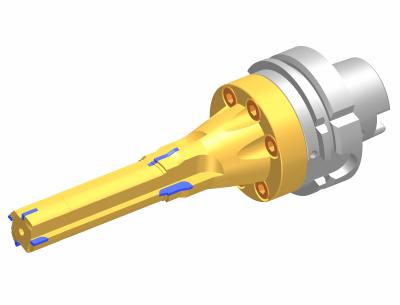

LACH DIAMOND offers dreboform custom-made tools, including special PCD step drills and combination tools for the automobile, supply and composite material industries. According to the company, knowledge gained in the long-term production of PCD profile tools (even with extreme shear angles) since 1978 guarantees the realization of all constructively conceivable profiles, and, therefore, success for the users.

Contact Details

Related Glossary Terms

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- polycrystalline diamond ( PCD)

polycrystalline diamond ( PCD)

Cutting tool material consisting of natural or synthetic diamond crystals bonded together under high pressure at elevated temperatures. PCD is available as a tip brazed to a carbide insert carrier. Used for machining nonferrous alloys and nonmetallic materials at high cutting speeds.

- polycrystalline diamond ( PCD)2

polycrystalline diamond ( PCD)

Cutting tool material consisting of natural or synthetic diamond crystals bonded together under high pressure at elevated temperatures. PCD is available as a tip brazed to a carbide insert carrier. Used for machining nonferrous alloys and nonmetallic materials at high cutting speeds.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.