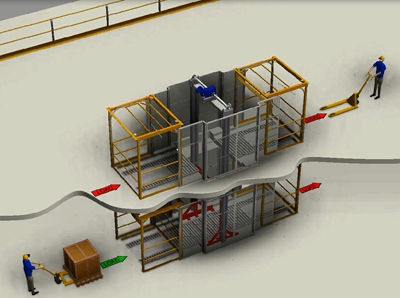

In response to customer needs for a safer material lift for automation duty applications, Wildeck's VRC product development and marketing team has unveiled a new fully integrated VRC system incorporating automated flush-mounted conveyors, with either a straddle or 4-post vertical reciprocating conveyor (VRC), and Wildeck Overhead Safety Gates at each level.

According to Hubert Schlegel, Director of Marketing at Wildeck, "The new FlexLoader VRC system turns a basic vertical lift — offered by several manufacturers, including Wildeck — into a safer, more efficient, and more automated material lifting system that seamlessly connects all levels of a work platform to make better use of the available space."

Wildeck&'s new FlexLoader material conveyor system incorporates the company's full-featured AutoSenz D-Series Overload Detection System (U.S. Patent No. 7,408,317) with automated horizontal loading and off-loading conveyors and Wildeck Safety Gates at each level. The system is therefore excluded from Elevator department inspections and provides code compliance in all 50 states, according to the company.

"It's the right product at the right time," states Schlegel, "since more manufacturers and distribution center operations are requiring increased material throughput to shorten product delivery times to customers."

According to Wildeck, the new FlexLoader VRC system improves the utilization of existing overhead cubic space and dramatically increases operational efficiency. The integration of Wildeck's Overhead Safety Gates at the in-feed and discharge points protects workers from the equipment and open shaft-way and prevents loads from being inadvertently pushed into or down the shaft-way.

The conveyor system and VRC are custom designed as a fully integrated system to meet the user's specific application requirements. The automated flush-mounted conveyor can either be supplied by Wildeck or can be supplied by the customer and factory mounted at Wildeck. Having a flush-mounted conveyor at each level makes it easy to load and off-load the VRC using a pallet jack or fork truck.