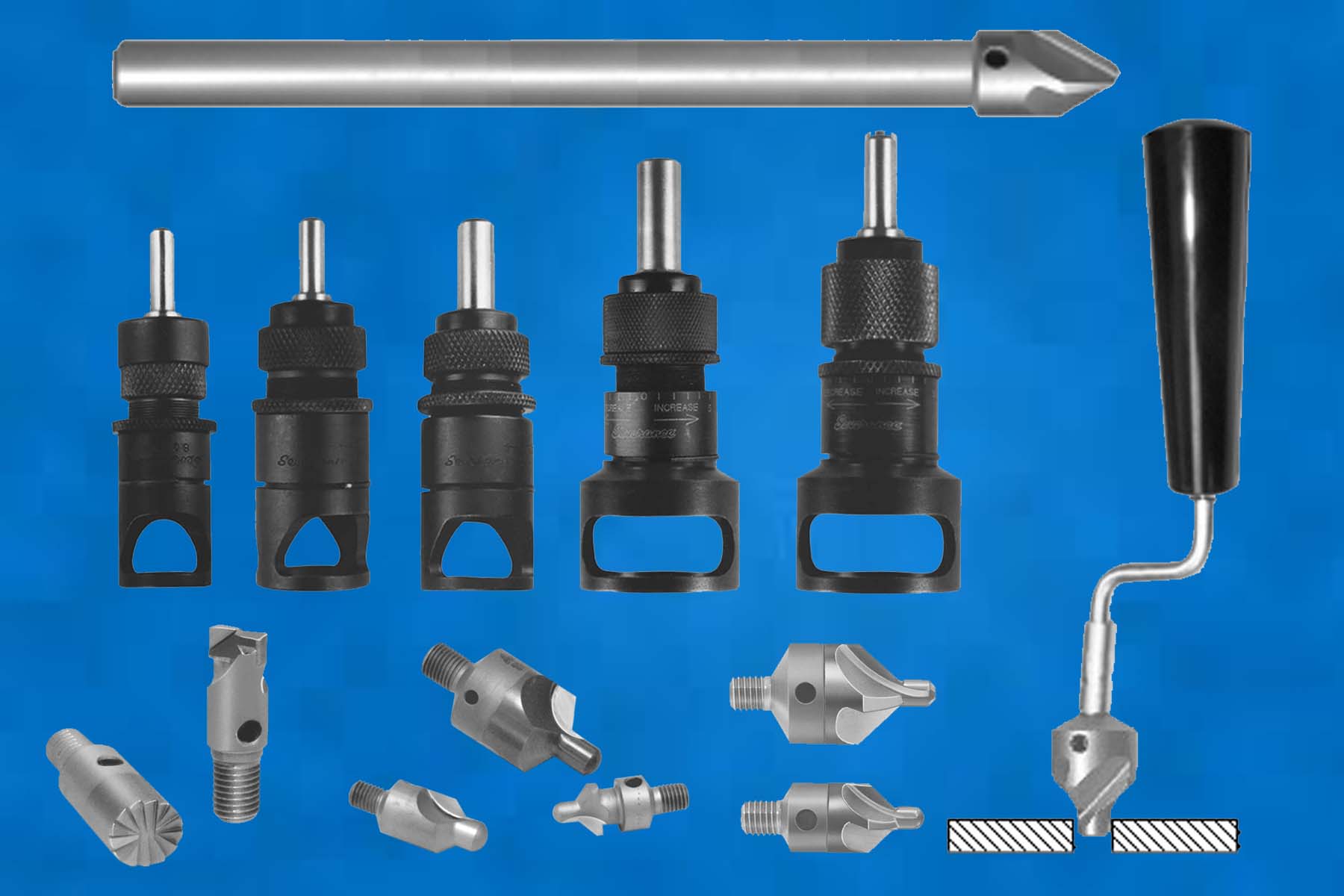

Stop countersinks and rivet shavers

Stop countersinks and rivet shavers

The Severance Micro-Stop Countersink system allows depth of cut to be adjusted (without tools, just a twist of the wrist) in increments of 0.001". The SC-25P, SC-25PR, SC-35P & SC-35PR unit provide a .0005" increment per click of the unit. The tool holders also provide a base to establish perpendicularity of the cutter to the work surface. Oversize bases can be supplied on special order, and bases can be modified to accommodate special clearance or contour problems.

The Severance Micro-Stop Countersink system allows depth of cut to be adjusted (without tools, just a twist of the wrist) in increments of 0.001". The SC-25P, SC-25PR, SC-35P & SC-35PR unit provide a .0005" increment per click of the unit.

The tool holders also provide a base to establish perpendicularity of the cutter to the work surface. Oversize bases can be supplied on special order, and bases can be modified to accommodate special clearance or contour problems. Non-marring Nylon feet are available to protect workpiece finish, if necessary.

The Micro-Stop Countersink system can be supplied with a wide variety of cutting tools for use wherever depth control is important.

All units come complete with a positive stop lock nut and a new SecurLock safety screw to maintain "preset" depth dimensions.

Chatter-free stop-countersinks cutters

Also known as Aircraft style Stop-Countersinks. These tools feature our patented 4-flute chatter-free flute design for smooth finishes, fast production, and quick chip removal. These precision-ground tools are made from high-speed steel or carbide and may be factory resharpened. Also available with special pilot sizes, angles, forms, and no pilots upon request.

Aircraft-style rivet shavers

Severance Rivet Shavers are used with Micro-Stop units. These end-cutting tools are designed to cut rivet heads, etc., flush to the surrounding surface. They are available in two series, multi-flute for fine finishing and two-flute for fast material removal.

Special stop-countersinks and units

Special diameters, pilots, flutes, and threads are available on the stop countersinks. Special units can be made.