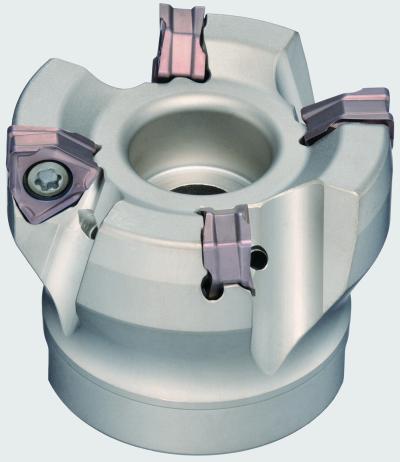

New from Sumitomo Electric Carbide Inc., the DFC Double-Sided 90º Milling Cutter is reportedly engineered for exceptional precision and efficiency. The high toughness and special shape of the DFC six-edge insert ensure long-term, stable cutting and high efficiency machining with high feed rates. Cutting edges are optimized to provide excellent surface finishes.

Low cutting forces and high wear resistance of Sumitomo’s DFC result in a long tool life. Machining accuracy is enhanced through the separation of the insert contact areas and cutting edges. In addition, a double-sided insert design reduces costs.

Recommended insert grades for steel include ACP200 and ACP300. For stainless steel applications, ACM200 insert grades are recommended and, for cast iron applications, ACK200 and ACK300 insert grades are recommended.

The DFC is available in 1” to 8” in standard, fine pitch and extra-fine pitch styles for a variety of applications. Maximum DOC is 6mm.

Contact Details

Related Glossary Terms

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling cutter

milling cutter

Loosely, any milling tool. Horizontal cutters take the form of plain milling cutters, plain spiral-tooth cutters, helical cutters, side-milling cutters, staggered-tooth side-milling cutters, facemilling cutters, angular cutters, double-angle cutters, convex and concave form-milling cutters, straddle-sprocket cutters, spur-gear cutters, corner-rounding cutters and slitting saws. Vertical cutters use shank-mounted cutting tools, including endmills, T-slot cutters, Woodruff keyseat cutters and dovetail cutters; these may also be used on horizontal mills. See milling.

- pitch

pitch

1. On a saw blade, the number of teeth per inch. 2. In threading, the number of threads per inch.

- wear resistance

wear resistance

Ability of the tool to withstand stresses that cause it to wear during cutting; an attribute linked to alloy composition, base material, thermal conditions, type of tooling and operation and other variables.